Report: Stone in hard landscaping

Since architects and planners started to realise the spaces between buildings could be as significant as the buildings themselves, stone has played an increasingly important role in the design of open spaces.

Natural stone continues to be the material of choice for many hard landscaping projects and the amount of stone being used in both commercial and domestic projects saw double digit growth again in 2015, with every indication that the growth continued in 2016.

With the growth have come moves by some of the major suppliers of stone for hard landscaping to strengthen their position in the market and increase their share of it.

The latest development has come from London Stone, which has three showrooms servicing all areas of London, a depot in Langley and a stone centre in Colnbrook (Langley and Colnbrook are in Berkshire). Its new move is the launch of a commercial range of natural stone hard landscaping, complemented by some concrete products to provide the complete solution for a project from one source.

Having established itself as major force in the supply of natural stones to the garden design and retail market sectors, the Walley brothers who run the company felt it was a natural progression to move into the supply of materials within the commercial and public development realms.

London Stone firmly believes its range of British York stones and imported stones has a proven track record of long lasting aesthetics and the technical properties that will perform in the most demanding of environments.

But, like the rest of the stone industry, natural stone is only part of the offer. The London Stone commercial range includes those concrete products, some designed to withstand the harshest of trafficking while still being pleasing to the eye.

The company is looking for opportunities to partner specifiers in the early stages of project design when there is the greatest scope for adding value to a project. Its CAD support capability can be an invaluable asset to the design team in that regard.

And if bespoke solutions are required, London Stone has its own stone processing capability on the doorstep of London.

Its in-house state-of-the-art machinery also means it can respond immediately to any particular requirements of a project rather than having to wait for alternative products to be shipped from abroad – and that can be a long wait if they are coming from China or India.

And with its own fleet of HGV vehicles with crane offload delivering into central London, the logistics of supplying what is required, when it is required are covered.

London Stone is not alone in courting the architectural commercial side of the sector. Hardscape, the provider of natural stone (and other) hard landscaping materials has opened a ‘Materials Lab’ at its headquarters in Eggerton, Lancashire, dedicated to providing inspiration, advice and product information to designers and clients.

When it opened in October more than 30 guests came along to see what was on offer.

The Materials Lab showcases the range of natural and man-made, ethically sourced materials from Hardscape – materials suited to all hard landscaping projects, from modest domestic projects to the largest urban regeneration schemes.

During the opening, Hardscape previewed cutting-edge 3D technology featuring digital models of hard landscaping materials to help in the visualisation and design of projects.

Representatives from landscape architect BCA Landscape and design agency and theme specialist Smiling Wolf wowed guests with a showreel of award-winning schemes created with the help of Artscape, Hardscape’s bespoke design service.

Hardscape’s technical experts are always on hand to provide insights into the features of the various materials supplied by the company and the capabilities of Hardscape’s machinery, which includes the latest hi-tech etching, sandblasting and waterjet cutting equipment – equipment that was used to create the extraordinarily artistic, award-winning Chinese granite hard landscaping in Douglas town centre on the Isle of Man pictured on the left. The designer was Andy Thomson of BCA Landscape.

Hardscape’s technical experts are always on hand to provide insights into the features of the various materials supplied by the company and the capabilities of Hardscape’s machinery, which includes the latest hi-tech etching, sandblasting and waterjet cutting equipment – equipment that was used to create the extraordinarily artistic, award-winning Chinese granite hard landscaping in Douglas town centre on the Isle of Man pictured on the left. The designer was Andy Thomson of BCA Landscape.

Mathew Haslam, Managing Director of Hardscape, says: “The Materials Lab is a unique resource for landscape architects to explore, be inspired by and get expert advice on materials. We are passionate about supplying quality materials and unbiased support to the industry and we hope that the Materials Lab will be a ‘go-to’ for hard landscaping inspiration to bring creative visions to life.”

Hardscape works with landscape architects across the UK and Ireland to assist them in selecting the most suitable products from an extensive network of global suppliers. It has been involved with projects ranging from transport interchanges and leisure and educational facilities to mixed-use urban spaces.

Another company actively seeking to expand in hard landscaping is Natural Paving Products, with headquarters near Doncaster, North Lincolnshire. It has opened a new, joint venture stone processing plant in India with a local company and intends to continue its exceptional growth by expanding into other overseas markets.

Employing more than 50 people in the UK Natural Paving Products focuses on the import, sales and marketing of its stones (and, lately, also porcelain paving called Vitripiazza) with distribution through a well-established network of merchants. At any one time it carries 45,000 one-tonne crates of finished product plus a further 20,000 crates in its manufacturing pipeline. Its stock is stored at its four distribution depots in Tilbury, Southampton, Grangemouth and Doncaster – with Doncaster also its warehouse and manufacturing facility in the UK.

Malcolm Gough, Group Sales & Marketing Director, says: “If we want to remain a leader in the landscaping industry, it is imperative we supply the market with what it is demanding as well as having a vision and ability to adopt future innovation. Many homeowners today lead busy lives and as a company we are passionate about ensuring our products are easy to maintain. This gives customers more time to enjoy the beauty of the product that has been installed.”

To assist with the maintenance of its product range, Natural Paving Products introduced the Pavetuf range of care and maintenance products in 2014.

It has even introduced its own standard for sandstone to help customers in their selection of suitable products for their particular applications. When developing the stone standard, the company worked closely with David Richardson, a consultant who is a Fellow of the Geological Society and past-President of Stone Federation Great Britain.

Natural Paving Products ranges are CE tested and marked, as paving is supposed to be, and its standards are based on the CE testing results to show performance across three key areas: water absorption, flexural strength and frost resistance.

Having a stone processing capacity in India, Natural Paving Products is a long-standing and active member of the UK’s Ethical Trading Initiative (ETI). Most of the stone the company sells comes from India and it has put some considerable effort and investment into the ethically and environmentally responsible sourcing of its materials.

In 2015 Natural Paving Products engaged with Kailash Satyarthi, an Indian Children’s rights and education advocate and an activist against child labour. He founded the Bachpan Bachao Andolan (BBA) Save the Children Movement in 1980 and has acted to protect the rights of more than 83,000 children from 144 countries.

It is largely because of his work and activism that the International Labour Organization adopted Convention No 182 against the worst forms of child labour. It has been adopted as a principal guideline by governments around the world and Kailash Satyarthi's work is recognised through the national and international honours and awards he has received, the pinnacle of which was the Nobel Peace Prize of 2014.

As part of the BBA auditing process, Kailash and his team have visited the Natural Paving Products joint venture factory in India and he is now working closely with the company on various charity projects. The aim is to eradicate child labour and improve education standards in the stone regions of India.

From an environmental perspective, the new Indian factory is one of few stone processing sites in India that recycles the water it uses, which can be a scarce resource there. And sandstone waste arising from processing is used for other building materials. Natural Paving Products monitors its carbon footprint against rival landscaping products and believes its ranges are among the most environmentally friendly.

The facility in India includes calibration machines, bridge saws, bull nosing machines, automated slab production lines and various texturing and sandblasting machines, all of which ensure the company meets the standards customers demand.

This year, Natural Paving Products will further increase its processing capacity along with its crate making and packaging facility in India, while it intends to expand its distribution in Europe and the USA. Last year it opened its first warehouse and offices in America in Atlanta, Georgia.

Mark Wall, Managing Director of the company comments, “The continued growth and success Natural Paving has experienced has been down to the support of our customers and the dedication and commitment shown by our employees. We are constantly looking at ways we can improve the business.”

All the companies mentioned above have proactively addressed the issue of slave labour in their supply chains. It is a very real issue in stone, especially with bonded labour in Indian sandstone quarries.

David Richardson, who worked with Natural Paving Products, is currently working on an ethical trading register for Stone Federation Great Britain. It is intended to help its members provide their customers with information they need to produce the Modern Slavery and Human Trafficking reports required in the Modern Slavery Act that came into force in April last year.

The statements must detail the steps the company is taking to ensure that modern slavery and human trafficking are not present in its business or global supply chains. The statement must be signed by a director and a link to the statement must be included in a prominent place on the organisation’s website homepage.

The Stone Federation register will be a sector specific scheme answering questions relating to stone supply, says David. “We have decided the best value will be achieved by focusing on the sector.”

It is only companies with a turnover of more than £36million that are required to produce the reports, which means many stone companies are exempt. But builders and developers that are big enough to have to produce a report will, no doubt, expect some input from their supply chain and might even choose stone suppliers and contractors who can provide evidence of ethical sourcing.

It depends how seriously anyone takes the Modern Slavery Act quite what impact it will have. But anyone who thinks it will disappear with Brexit is going to be out of luck. It did not come from Europe. It was Theresa May, as Home Secretary, who introduced the Act, the first of its kind in Europe and one of the first in the world. (You can read more about the Modern Slavery Act and its impact on the stone industry at bit.ly/StoneSlaves.)

One company that does have to produce its own report under the provisions of the Modern Slavery Act is the market leader in hard landscaping product supply, Marshalls, which has a turnover 10 times the £36million threshold in the Act.

Marshalls has always been a leader in tackling issues of ethical sourcing and had its 11-page Anti Slavery and Anti Human Trafficking Policy and Disclosure Statement, signed by Chief Executive Martin Coffey, posted on its website almost as soon as the Act came into force. Marshalls operates its own quarries and concrete product manufacturing plants in the UK, as well as importing a lot of stone. Its directors take seriously ethical and environmental issues and understand the value to the actively traded PLC of being seen to do so.

The UK’s Ethical Trading Initiative (ETI), which is funded both by the government and the companies that participate in it, is recommending that companies should place their Modern Slavery Statements in the Business and Human Rights Resource Centre’s Central Registry for Modern Slavery Statements (bit.ly/BusinessSlave), arguing that it provides an independent, credible, free, open and accessible repository that is accountable to the public interest.

There has always been a concern that the Modern Slavery Act might simply produce a standard form of words posted by companies in order to comply with the law. To some extent that does seem to be happening, although it is not an accusation that can be made of Marshalls’ response.

Joanna Powis and Shannon Diggory reported on statements so far produced on international law firm Reed Smith’s ‘employment law watch’ on 1 December.

They say press reaction to date has been critical of how businesses have approached the reporting requirement, with statements being labelled ‘lacklustre’ and formulaic and criticised for not going far enough towards tackling modern slavery issues. Up to a third of companies are reported to have failed to comply with basic elements of the reporting provision, such as including a director’s signature or putting a link to the statement on the organisation’s web homepage.

A report by Ergon Associates quoted by Joanna Powis and Shannon Diggory, considers the topics best covered in published statements so far are explanations of the organisation’s structure and policies covering modern slavery. Least well-described are key performance indicators (KPIs) being used to assess the effectiveness of the company’s modern slavery policies. The authors say: “This comes as no surprise given it is difficult to come up with KPIs that would be both appropriate and effective for a lot of businesses.”

Ergon Associates says contractor relationships are a key gap in statements, particularly as outsourced services may pose significant risks of including slavery in their supply chains.

In terms of the legislation itself, changes are already pending in the form of the Modern Slavery (Transparency in Supply Chains) Bill, which will require companies to publish their slavery statements in their annual reports as well as online.

Qualifying companies that have not published a slavery and human trafficking statement are warned they will be excluded from tendering for public sector contracts, which will be a real influence on builders and developers involved in hard landscaping. Those big enough to have to produce reports will be expecting help from their stone suppliers to show evidence of diligence, at least, in checking their supply chains.

As for Marshalls, it continues to see sales growing, reporting revenue up 3% to £375million in the 11 months to the end of November. Growth has been particularly strong in the domestic market, with second half sales up 15% in the five months to the end of November compared with the same period in 2015 and looking good for the year ahead. Growth had accelerated after the June referendum.

Marshalls’ sales to the public sector and commercial end market now represent approximately 64% of the company’s sales. Commercial sales in 2016 were expected to be broadly in line with the previous year.

It continues to invest in its UK natural stone assets and the first of its new machines designed to reduce processing costs were installed in October. It says it is looking for bolt-on acquisitions where appropriate.

CED supplies the stone for Ireland’s Bog Oak Trophy winner

A private garden in Co Fermanagh has landed Belfast’s Cameron Landscapes Ireland’s coveted Bog Oak Trophy for the seventh time.

Held each year by the Association of Landscape Contractors of Ireland (ALCI), the awards celebrate the work of the Irish landscaping industry, with categories to recognise residential gardens, commercial projects and sports fields.

But then there is the Bog Oak Trophy. This is for the overall winner. It is a great honour to be awarded the trophy once, let alone seven times. There is hushed expectation among the landscapers at the awards ceremony as they wait to discover who it will go to.

This year, the awards ceremony was held in Titanic Belfast on 11 November. Entrants in the all-Ireland scheme, including the winner, are deliberately kept in suspense about whose work has been judged best and there is much speculation ahead of the announcement. Will it be a residential, commercial or a sports field project?

The awards were presented this time by guest of honour Norman Fulton, a Director of Kilkenny Mechanical Handling Systems, and it was his duty to hand the Bog Oak Trophy to Cameron Landscapes, a family-run business founded more than 40 years ago.

The company first won the Bog Oak Trophy more than 30 years ago. In the intervening years the company has not only demonstrated it has maintained its high standards by winning six times more, it has also expanded, opening a garden centre of its own in Ballylesson Road, Belfast.

The hard landscaping in the winning garden was supplied by stone specialist CED, which has five depots around the UK, including one in Omagh. Stones selected for the project included Blue Grey granite edging, Blue Grey granite paving, Blue Grey granite bullnosed steps, Silver Grey granite cropped setts, black basalt cropped setts, Silver Grey granite aggregate, Scottish beach cobbles and the CEDAdrive surface – not insignificant for a first-time order!

James Kane, CED’s Omagh depot manager, was delighted to be associated with the Bog Oak-winning project. “Congratulations to Geoff and his team on their success at the ALCI awards and their Bog Oak Trophy win,” he said afterwards . “The beauty of our products is truly brought to life through excellent workmanship and quality design – and the winning garden is a perfect example of that. It has been an absolute pleasure to supply and work with Cameron Landscapes, who have fast become valued, regular customers. We look forward to working with them again in the near future to create many more beautiful projects.”

As James says, Cameron Landscapes has since become a regular CED customer and now also has a display of CED stone and porcelain products at its garden centre.

Stone continues to be popular in hard landscaping

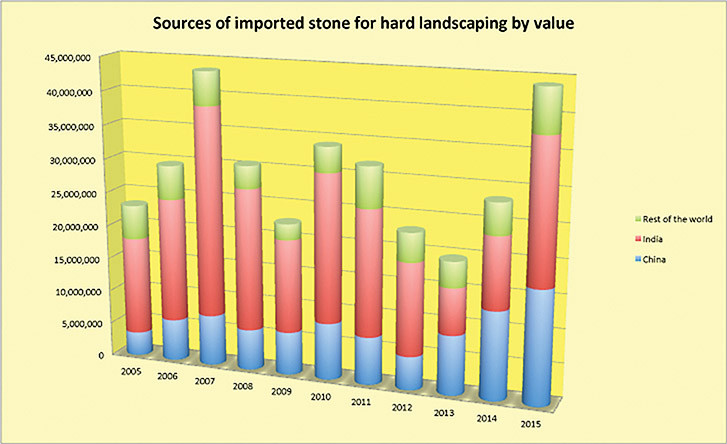

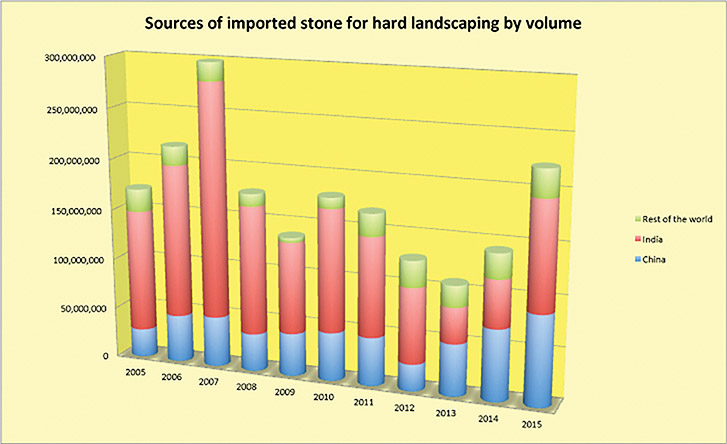

India and China continue to dominate the stone hard landscaping sector in the UK, supplying sandstone and granite at competitive prices. According to the figures here from HM Revenue & Customs, in 2015 China and India between them accounted for 88% of the volume of natural stone hard landscaping imports and 86% by value.

Most of the rest comes from Europe – and European stone has been making a come-back lately. The figures will continue to be updated for a while, but the 10 months to October 2016 had already seen European imports ahead of 2015 figures, accounted for mostly by Italy, which is a significant source of the porphyry that is popular for hard landscaping.

Most of the rest comes from Europe – and European stone has been making a come-back lately. The figures will continue to be updated for a while, but the 10 months to October 2016 had already seen European imports ahead of 2015 figures, accounted for mostly by Italy, which is a significant source of the porphyry that is popular for hard landscaping.

The amount of British stone used is unrecorded, with hard York stones and Pennant highly regarded and frequently used in prestigious projects, along with a variety of other local stones, especially granite and slate and some limestones.

However, the price advantage of the imported stones means they tend to get selected more often and imports provide a good indication of trends for the use of stone in hard landscaping.

The use of stone in hard landscaping has been growing strongly in the past few years. It is too early for final figures for 2016 yet, but the monthly figures for the 10 months up to October last year indicate the trend continued in 2016.

Landscaping companies make a charitable contribution

Many stone companies make a contribution to charities in the areas in which they work and lately London Stone, CED and others have been making a difference.

London Stone, which has just launched a commercial range of hard landscaping (see main story) is doing its bit to assist in the creation of hospice gardens by donating £10 to the charity Greenfingers every time a customer signs up to its Landscape Specialist Scheme.

There is no downside for the landscapers because the scheme is free to join and brings with it all kinds of benefits and rewards.

Having become a Greenfingers charity partner, London Stone has already donated more than £650 through it scheme.

Greenfingers is creating outdoor spaces of peace and relaxation at children’s hospices for the children and their families. There is such a demand that the charity says it will have its hands full for the next 15 years with the commitments it has so far made.

And the Midlands depot of natural stone hard landscape supplier CED, based in Langley Mill, Nottinghamshire, Natural Paving Products, Old Hall Plant Nurseries, Miles Nurseries, JA Stephens Builders Merchants and David Greaves Landscape & Construction have all contributed to garden designer Jackie Setchfield’s creation of Rosie’s Garden at West Bridgford Junior School in the south of Nottingham.

The garden is in memory of 11-year-old Rosie Perry Jones, a pupil at the school who died in 2014 five months after being diagnosed with ovarian cancer.

The school discussed what would be a fitting memorial and liked the idea of a garden by Chelsea Flower Show Gold Medal winner Jackie Setchfield from Olive Tree Garden Design, whose children attended the school.

The school set about raising the money to create the garden but was still £20,000 short when the trade specialists stepped in to make it possible. The garden opened shortly before Christmas with carol singing by pupils from the school and the cutting of a pink ribbon by Rosie’s sisters, Jess and Millie.

Rosie’s mum, Diane, dad Guy, family, friends, and everyone who contributed to the garden were at the ceremony.

King’s Cross

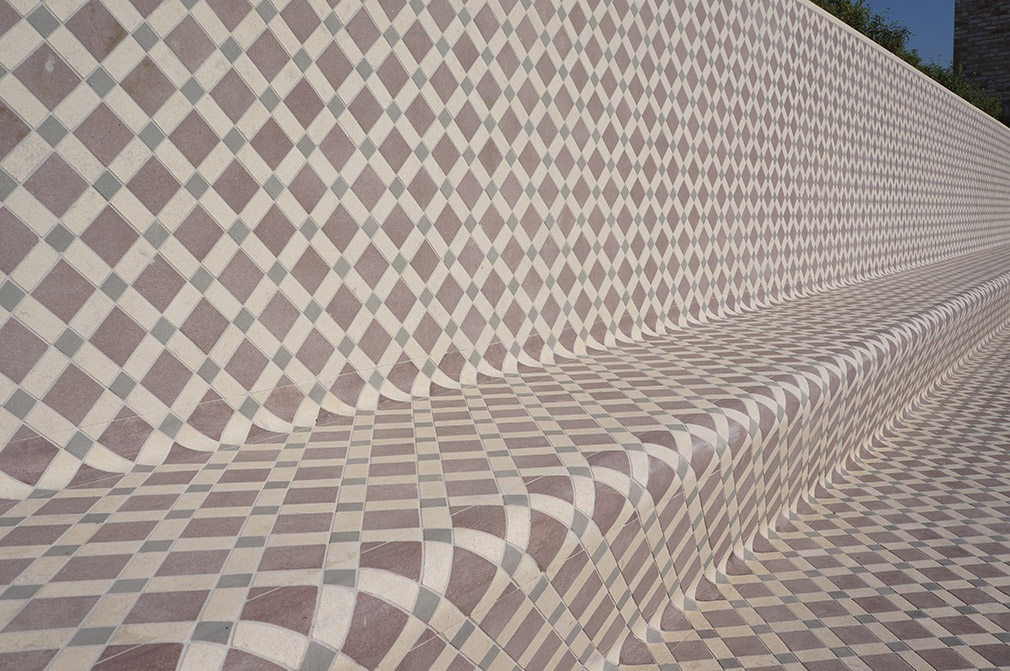

The pictures here show AKDN Gardens in London, part of two developments commissioned and owned by the Aga Khan Development Network (AKDN), a group of development agencies, at King’s Cross. The first building, Victoria Hall,  provides student accommodation, while a second, due to finish next year, is an academic and office building to house the teaching and administration spaces for the Institute for the Study of Muslim Civilisations (AKU-ISMC). The hard landscaping is by specialist stone & tiling contractor Keystone Restoration Ltd from Longfield, Kent, to the designs of Lebanon-based architect Valdimir Djurovic of Vdla Landscape Architecture. It involves green spaces throughout – roof gardens, terraces, courtyards. Each space represents a garden from a different region of the Islamic world represented by contemporary landscape designs that don’t attempt to copy the original references, but rather capture their essence. It has already started winning awards for its design. We will bring you a detailed report in a future edition of Natural Stone Specialist.

provides student accommodation, while a second, due to finish next year, is an academic and office building to house the teaching and administration spaces for the Institute for the Study of Muslim Civilisations (AKU-ISMC). The hard landscaping is by specialist stone & tiling contractor Keystone Restoration Ltd from Longfield, Kent, to the designs of Lebanon-based architect Valdimir Djurovic of Vdla Landscape Architecture. It involves green spaces throughout – roof gardens, terraces, courtyards. Each space represents a garden from a different region of the Islamic world represented by contemporary landscape designs that don’t attempt to copy the original references, but rather capture their essence. It has already started winning awards for its design. We will bring you a detailed report in a future edition of Natural Stone Specialist.