There are now so many adhesives, sealers, cleaners, enhancers and all kinds of other treatments available for stone that fixers and tilers are putting their hands up in defeat. But stay calm. Help is at hand.

There’s just a hint of despair and more than a hint of frustration in the voices of some of the calls we receive at Natural Stone Specialist magazine from tilers and stone installers. They are installing a stone they have not used before and they don’t know which products to use to stick, seal, grout, enhance or otherwise use with it.

Or else they have used a product they happened to be able to buy locally and the result is an outcome they were not expecting and their client is less than happy with. Now they are looking for another product to solve the problem.

There is certainly no shortage of products to choose from. So many, that one NSS reader described it as being like tomato ketchup – whatever packaging it comes in, it all tastes the same.

Not everyone would agree. What one person swears by another might swear at.

Stones (and other building materials) are the same. What suites one will not necessarily suite others.

Certainly the manufacturers of products for fixing and treating stone have identified a lot of different uses for their products and created a lot of separate products, where there used to be one, for various applications. Not all fixers and contractors are convinced of the need for so many and plenty find it confusing. Some also end up making the wrong choice.

Old hands often swear by one brand or another, while their younger colleagues more readily turn to the internet for enlightenment.

But competition keeps prices keen and stimulates product development – and what a lot of development there has been in the chemical products for keeping stone (and other materials) where they are supposed to be and looking as good as the day they were installed, or returning them to that condition when they have altered.

Competition in a market with so much choice probably does fairly quickly eliminate any products that are not up to scratch. The result when it comes to fixing, sealing, enhansing and cleaning stone is that the products available will do what they say they will. They might do a lot more, but you never know.

People installing stone are not likely to be chemists but neither do they need to be. They can generally read and the packaging of most products contains plenty of instructions for using the product and warnings about how not to use it. Often too much. There has to be in these litigious times so the manufacturers don’t get sued. But the result can be that the advice and warnings are not read.

We are probably all familiar with the saying: “When all else fails, read the instructions” and have also probably been guilty of it, especially when we think we are familiar with a product or a method.

But because of the variety of specialist products, and more being launched all the time, it is worth checking. Even familiar products have their formulas changed occasionally.

The extensive choice of manufacturer and product is exacerbated by just about every tile shop and kitchen studio offering the products for sale – and no doubt maintaining that the brands they sell are the best available.

It has made it difficult for the traditional stone distribution route to keep up. Some offer established, tried and tested brands that have proved effective with stone for a long time – General, Jolly, Mapei, Sprint, Bellinzoni, BAL, Ardex and the like – quite often alongside market leader Lithofin’s wide offering because it is commonly asked for.

LPE Group, which sells Breton CNC machines and Comandulli edge polishers, has taken a different route. When it launched its LPE Tooling business last year there were various chemicals included. But it has since taken them out of stock. It will still arrange to supply customers with whatever they want, but they have to buy a box at a time and LPE arranges for the manufacturer to ship it directly to them.

As well as the machinery and other products it sells in the UK, LPE is European distributor for American-made Laser Products’ digital templaters and Omni3 materials handling products. And it would rather have those in its warehouse than stacks of chemicals that compete with any number of alternative products from an even larger number of suppliers.

For the contractor and fixer having trouble deciding which products to use, there is help at hand beyond the packaging. There are videos on YouTube of just about any job you care to think of. You have to decide for yourself the veracity of the advice given, although the videos posted by manufacturers are presumably accurate descriptions of how they want their products to be used.

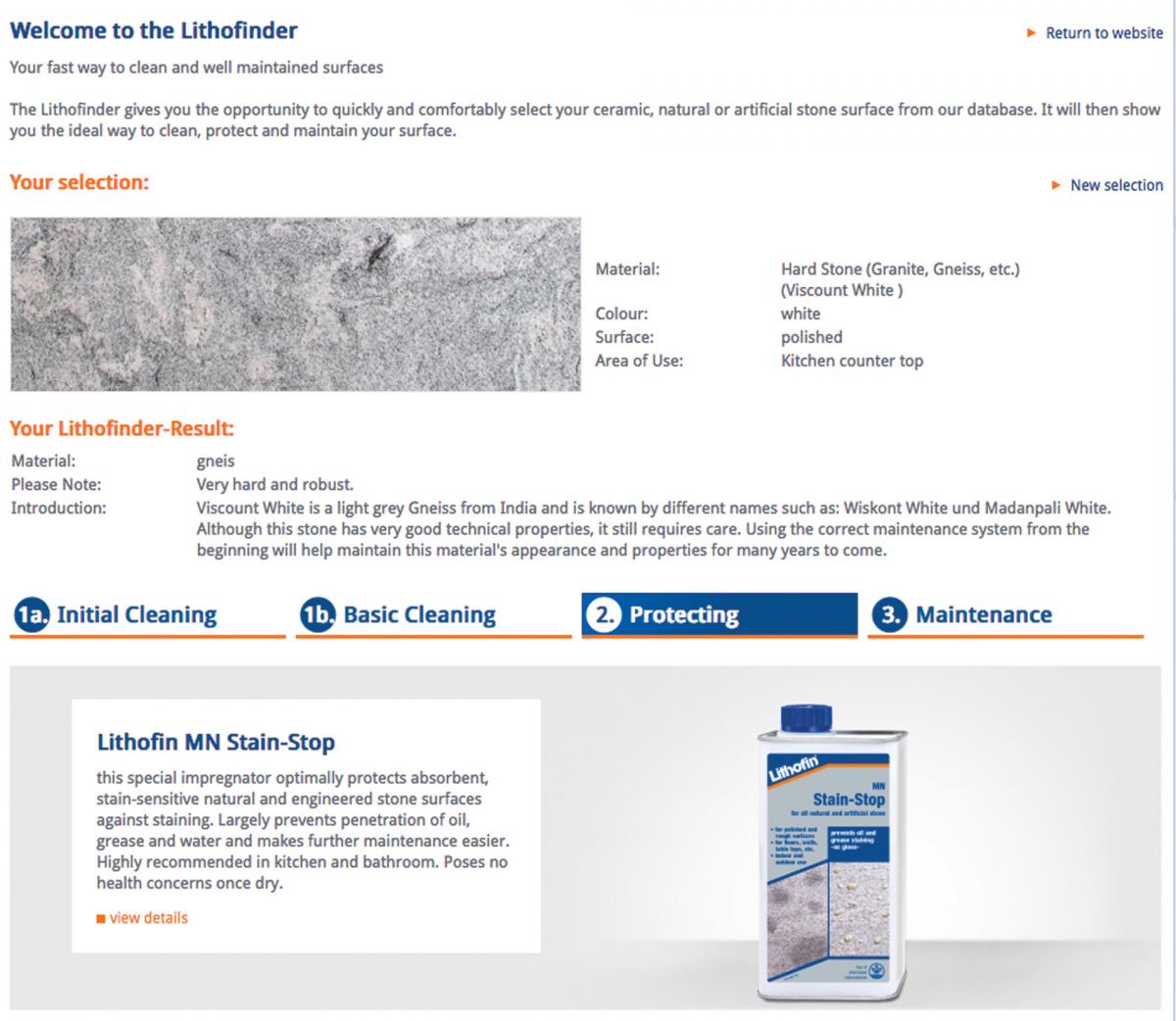

Manufacturers’ and distributors’ websites are also getting better all the time at helping with the choice of product for various applications and materials. Lithofin, which has for decades considered education an important part of its marketing, asks a number of straightforward questions on a section called Lithofinder on its website.

Other manufacturers (DryTreat, for example) have a similar section on their websites. You answer one question at a time and it moves on to the next, so it is not daunting, and it finishes up recommending a product.

Other manufacturers (DryTreat, for example) have a similar section on their websites. You answer one question at a time and it moves on to the next, so it is not daunting, and it finishes up recommending a product.

Then there is help you can carry around with you. Instarmac has just launched a new product planner App, which you will appreciate if you have ever been stuck on site with no internet connection and need to find out how quickly your tile adhesive will take to set; when your pothole repair can be trafficked; which smoothing underlayment you should use; or anything else about any of the Instarmac range – UltraCrete, UltraScape, UltraTile, UltraFloor, Wondertex and Granfix. Each range has its own dedicated pages so you can find what you are looking for easily and quickly.

What’s more, each product has its own enhanced product calculator, technical and safety datasheets and even tutorial videos. And the App will let you know when another product is launched – products like the UltraFloor SuppressIt launched in June. This is a ready to use single component moisture suppressant primer membrane. Although it is water-based, it dries rapidly. And although it must be applied in two coats it is not going to delay a project because it is designed to suppress residual construction moisture, which means the floor coverings can be applied soon after treatment. SuppressIt followed FillIt, a deep filling concrete for carrying out deep section repairs such as filling unwanted drainage channels.

If the App is just what you need, it is yours free from Google Play and the App Store.

There is even help in the real world (as opposed to the virtual world) with help lines and training courses from many of the manufacturers. Some of the distributors will also work with manufacturers to provide training for customers.

Lithofin, after more than 60 years’ experience, has a product range that covers just about everything you could possibly need throughout an installation, problem solving and general cleaning for all stone surfaces, both interiors and exteriors.

It provides an effective range of products for the protection and maintenance of natural and engineered stone and other materials. Impregnating sealants such as Lithofin MN Stain-Stop provide effective stain protection for natural stone when the stone is maintained with Lithofin’s daily / weekly-use cleaning products – Wash & Clean and Easy Clean for worktops.

The aftercare, or routine maintenance, is essential for the longevity of the sealants and impregnators. Lithofin products, used correctly, will ensure that stone remains protected and in pristine condition for a long time.

Lithofin MN Stain-Stop ECO is the next generation in water-based protective treatments. Easy and safe to apply, this high quality impregnator is an excellent water and oil repellent on porous natural stone surfaces (such as limestone). However, the chemical properties of the natural stone are not changed, so acid sensitive limestone or marble will remain sensitive to acidic substances. If you want to really bring out the beauty of stone there is also Lithofin Colour Intensifier, designed to enrich the stone’s natural colour.

Whether you are restoring or installing, a cleaner like the Lithofin MN Power Clean removes grease and oils and all kinds of ingrained dirt.

In the UK, Casdron Enterprises Ltd is the sole agent for the Lithofin Range. It has an experienced team of technical advisor’s on hand to assist with any product queries and problem solving. Its Technical Helpline is available Monday to Friday from 8.30 in the morning to 5-o-clock in the afternoon (excluding bank holidays) on 01962 732126. And the Casdron website includes specifications for architects and designers that can be downloaded.

Lithofin is at Marmomacc in Verona at the end of September and Casdron will be at next year’s Natural Stone Show in London (25–27 April), so if you would like to speak to their Technical Advisors face-to-face and learn more about the Lithofin range, make it a date.

Of course, Lithofin is not the only company that will be exhibiting at Marmomacc or the Natural Stone Show in London. There will be plenty of chemicals companies happy to provide you with the solutions you are looking for at both. Another of the regulars is Fila.

In Verona, Fila is showcasing its award-winning Green Line range, which is part of its Green Action Plan covering the selection of raw materials, processing methods, safety systems, continual personnel updates and an eco-commitment reflected throughout the manufacturer’s whole operation.

One of the products it will show in Verona is Salvaterrazza, which is new to the UK. It provides a complete repair and protection solution for all wet applications, from swimming pool tanks and surrounds to steam-rooms and changing rooms.

Designed for stone, porcelain, ceramic and concrete, the solution consolidates surfaces without creating a film. It prevents water penetration, avoiding mould and efflorescence and protecting against frost damage.

Ready-to-use Salvaterrazza provides high coverage, does not alter the appearance of the surface and will not ‘yellow’ with age. It also protects grouted joints.

It is brush-applied to penetrate fissures and form a chemical bond, consolidating cracks up to 1mm deep. Once applied, it allows the material to ‘breathe’, avoiding any issues with rising damp. As well as its use in leisure environments, it can also be used on damaged and weather-worn paths and patios.

Before application, all surfaces should be cleaned with a suitable deep cleaning treatment such as Fila’s PS87 degreasing detergent or, for acid-resistant surfaces, Deterdek, a fume-free buffered acid solution. Salvaterrazza should then be worked into the surface and any excess treatment removed. The surface will be ready to walk on after 24 hours.

Then there’s Tilemaster’s Tanking System, which offers an advanced waterproofing barrier for wet rooms and swimming pools. This ready-to-use sealing system is designed to prepare and seal substrates – from plasterboard to concrete block – ahead of stone, ceramic and porcelain installation. Its flexible composition gives a fast, easy application inside or out and tiles can be fixed after four hours.

The co-polymer system comprises a pre-mixed waterproofing paste reinforced with fleece tape and preformed corner tapes (all kit contents are also available individually).

The system stabilizes water sensitive substrates and provides a waterproof seal in damp and even submerged environments. It’s flexible, so suitable for use with underfloor heating and in areas subject to light movement or vibration.

The preparation products are offered alongside a comprehensive range of adhesives and grouts. And Tilemaster is a UK company with expert advice and customer support on hand.

Of course, fashion plays its part in product development. The fashion for wet rooms and swimming pools has led the developments in tanking and waterproofing and is now playing its part in their use in projects for moving interiors as seamlessly as possible into exteriors.

The growth in the use of natural stone for both interior and exterior paving is not coincidental in the trend. Natural stone is one of the few materials that lends itself readily to use inside and out in this way.

There are issues involving thermal barriers, different thicknesses of stone inside and out, making joints line up if they are different sizes to accommodate drainage outside… But they all can and are being overcome.

When you think of interiors being taken outside you tend to think of a room with large, foldaway doors leading on to a patio, but the inside-outside dream also extends to balconies and roof terraces.

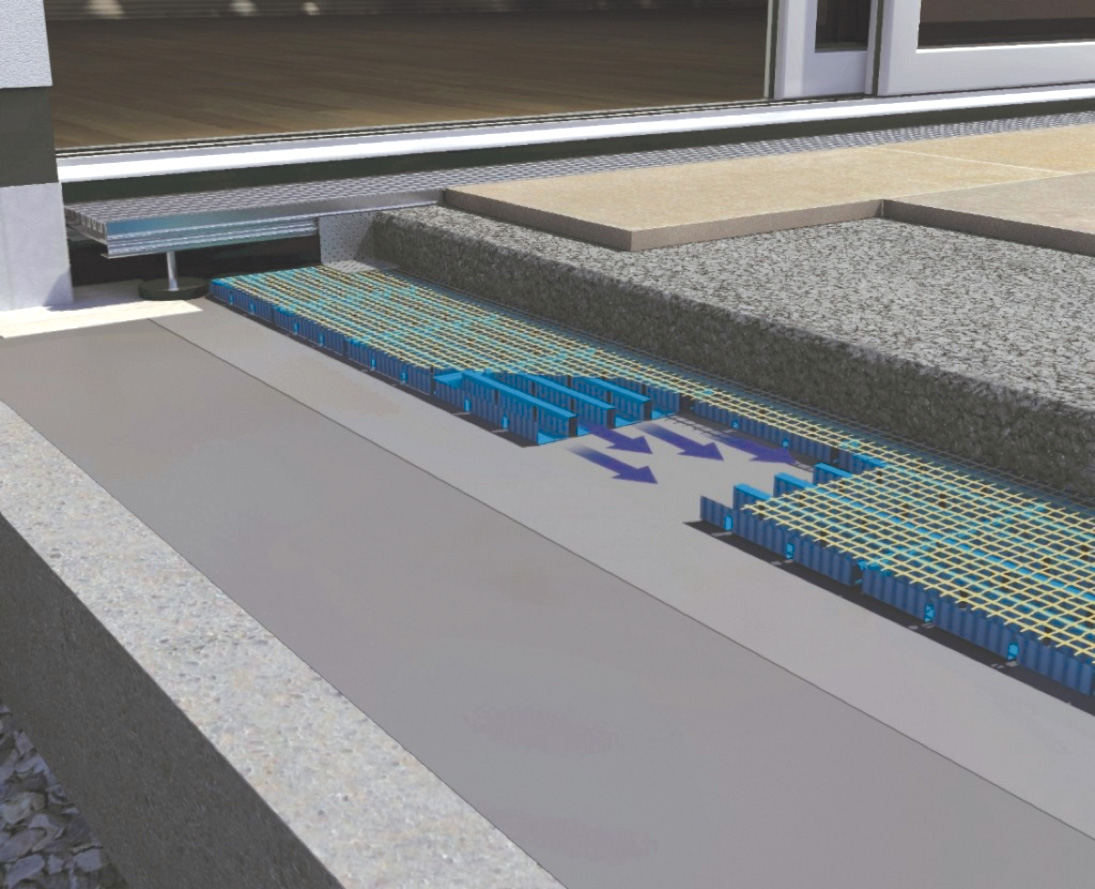

To satisfy this whole market, BAL launched a new problem-solving external tiling system for balconies, roof terraces and ground terraces in August that it previewed at the Surface Design Show in London in February. It goes under the name of Gutjahr, which it takes from a company bought by BAL’s German parent, Ardex, in 2014.

It is a whole system and requires some understanding, so BAL is offering help at the new training centre it opened at its head office in Stoke-on-Trent last year. The company had an old warehouse not doing much so it refurbished it as a state-of-the-art education centre, where it now holds normally one- or two-day courses, although that is flexible. Training can also be taken to a contractor’s own premises. You can find out more about BAL’s training on its website or call Janet Webster, the Training Administrator,on 01782 591120.

The Gutjahr System offers designers and contractors drainage and ventilating and uncoupling solutions to protect outdoor coverings against the British weather.

Alex Underwood, Head of Marketing at BAL, says: “External tiling is a fast-growth segment in the UK as the trend for inside-outside living thrives.

“The new products represent a complete new range of solutions for the BAL portfolio and work as a system with current BAL preparation, adhesive, grout and sealant products. This means, for the first time, architects, designers and contractors are provided with a true one-stop-shop for balconies, terraces and external ground floors.”

As well as avoiding frost damage, staining and water damage when using tiles externally, the system can reduce the weight loading on a balcony through thinner assemblies, lighter materials and limiting water absorption and retention, which in turn reduces water loading.

Gutjahr has a proven track record of delivering trouble-free coverings across Europe from large prestigious commercial projects (Amsterdam Library, The Palace of Hambach, the Weimar National Theatre) to smaller domestic projects over the past 25 years. It also invented (and patented) its passive capillary AquaDrain surface drainage system, ProFin edge profiles, AquaDrain grates and ProRin guttering. They are simple to install and provide rapid, high volume drainage.

If a comprehensive solution is not what you are looking for, there are almost as many individual products for fixing, cleaning, enhancing, protecting and restoring exterior stonework as there are for interior stonework. One company that has become well known for a range it introduced and sells as Pavetuf is Natural Paving Products (UK).

Natural Paving Products sells paving and landscaping natural stone (and more recently also some specialist man-made products). Malcom Gough, the company’s Sales & Marketing Director, says they became fed up with visiting sites where there were complaints and their stone was being blamed when the culprit was the materials used with it.

So Natural Paving Products decided to sell its own range of priming slurry, jointing mortar and compound, sealers, cleaners and other products for its customers to use in conjunction with the stone it sells.

“We thought: let’s get into this market and show them how it should be done,” says Malcolm. So they visited British chemicals companies, told them what they wanted and, two years ago, launched the range.

“We have done this in a Rolls Royce type of way – it’s the best,” says Malcolm. “Our products genuinely work – they do what we say they will.”

Making the right choice

By Lisa Breakspear, Sales & Technical Director, Fila UK

There are so many different products available for sealing and cleaning stone, some good, some not so good. With so much choice and sales-related ‘noise’, it can be hard to know what the best options really are. There’s also a whole host of aggressive acids and detergents that are unsitable for use of limestone and marble. So, how can you make an informed choice?

It’s well worth opting for a quality brand that provides a complete cleaning, sealing and maintenance regime, so you know the products are compatible. If you’re unsure, always ask for advice. Most manufacturers provide technical help lines and many, like Fila, are able to test materials if there’s any doubt about the best way forward.

Stone isn’t a difficult material to look after but a degree of care does need to be taken. In general, stone should be sealed straight after installation – but only once it has been thoroughly cleaned with a suitable detergent! Water will not remove manufacturing and fixing residues and, as a result, a sealant will not be properly absorbed. So, what is a suitable cleaner?

In general, a pH neutral cleaner designed for the job is the best option. The pH value should be clearly displayed on all detergents. pH7 is neutral. Less than pH7 is acidic; more and it’s alkaline. Vinegar and lemon have a pH value of around 3. Acid detergents are much lower. They will etch (or eat into) Calcium carbonate, so they should not be used on limestone or marble. Likewise alkaline bleach. It will damage a polished marble surface.

In terms of sealers, it’s no longer the case that solvents out perform solvent-free products. There are some fabulous

solvent-free treatments on the market (like Fila MP90 Eco Plus). As well as being safer and more eco-friendly, their water-base means they can be applied over residual moisture, whereas solvents must be applied to a completely dry surface. A water-based product can save time and money.

Look out for a sealer that’s been certified as food safe, too, so you will be able to use it to treat marble and granite tops where food is prepared or eaten.

Quality manufacturers that provide whole regime products, like Fila, also offer treatments for maintenance and troubleshooting – from deep cleaners to rust removers. Again, by using treatments from the same range you can be sure that they will work successfully together.

If in doubt, look out for products recommended by the company that supplied the stone, as they will often have worked with the chemical company on the best solutions in terms of the stone’s performance and longevity.

Lisa Breakspear at Fila UK (01584 877286 / filaUK@filasolutions.com) will be happy to help you choose the right product.

Stonegate finds the ideal glue for stone

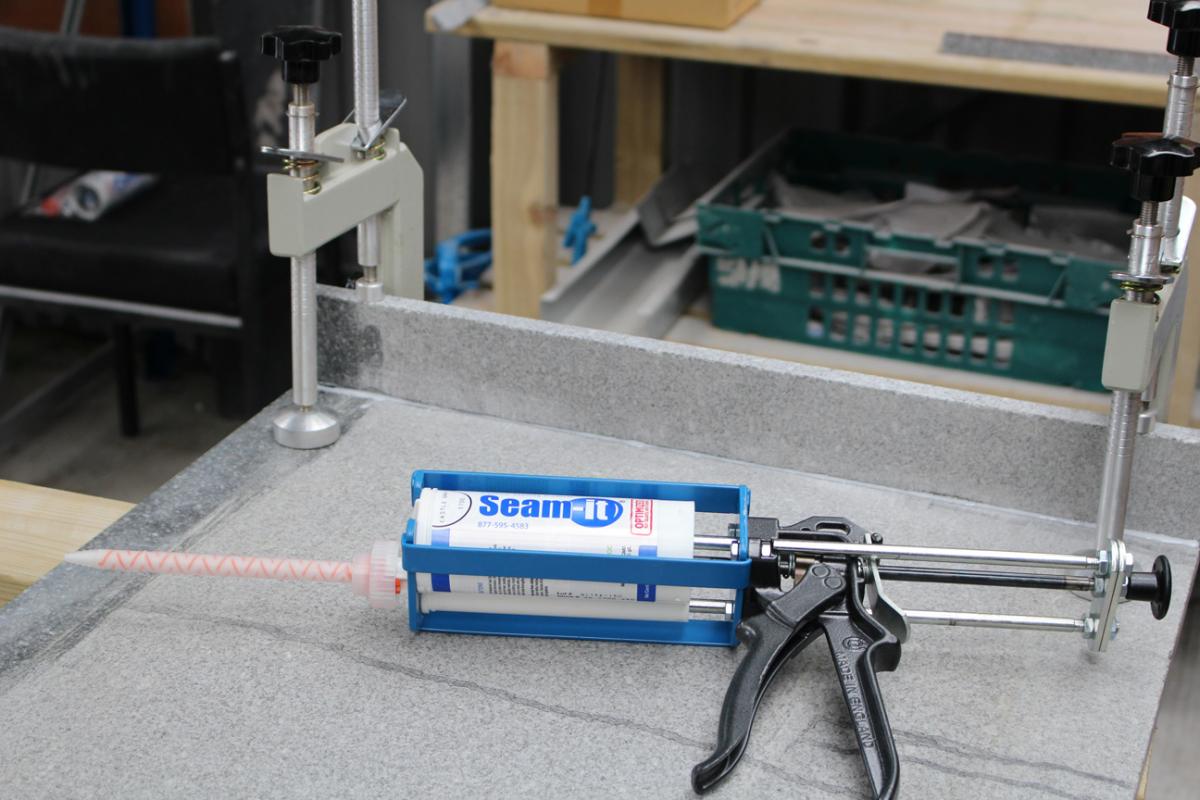

Stonegate Precision Tooling Ltd has taken on distributorship of the American Scigrip range of Seam-It MMA adhesives.

Stonegate Precision Tooling Ltd has taken on distributorship of the American Scigrip range of Seam-It MMA adhesives.

Scigrip Adhesives are a combination of polymers and impact modifiers that create an adhesive that combines the strength of an epoxy with the elongation properties of polyurethane.

For the technically minded, epoxies tend to have a tensile strength of 27-36MPa, elongation of 2-6% and Young’s modulus of 900-1400MPa, while a polyurethane has tensile strength of 6-14MPa and elongation of 100-300%.

The technology of an MMA bridges the gap between the tensile strength of epoxies and the flexibility of polyurethanes, giving the ideal result for the stone industry.

As time efficiency is key for stone workshops, Stonegate understood the importance of open time before curing begins, but then quick curing to full bond. Seam-It MMA gives eight minutes working time for positioning and clamping then achieves a full bond within 20 minutes. It even has a shelf life of two years.

Traditionally, pigments have been hand mixed for colour matching adhesive to the stones being used. But Scigrip has worked extensively with leading slab suppliers to produce a premixed colours matching service just by calling Stonegate on 01482 620400.

And now from Stonegate comes Mastidek Glue for Dekton from Cosentino, a new generation bi-component resin. Stonegate is a Cosentino approved supplier for Dekton tooling & consumables and has Dekton colour-matched Mastidek available from stock.

This glue is completely invisible and will not yellow or create shadows around cracks or seams. Reactivity is slightly influenced by temperature, but you can expect gelling time within 15-20mins and it will no longer be tacky within 60-70mins.

Thanks to Stonegate’s programme of continual training and learning, its team can offer informed advice regards the options of adhesives and sealants used in the industry.

The Weber training agenda

At the purpose-designed Saint-Gobain Technical Academy in Flitwick, Bedfordshire, Weber’s training programme embraces all categories of the company’s diverse product range, including tile fixing, technical mortars and flooring systems, covering topics such as tiling on to underfloor heating, waterproofing and tanking, and levelling compounds.

At the purpose-designed Saint-Gobain Technical Academy in Flitwick, Bedfordshire, Weber’s training programme embraces all categories of the company’s diverse product range, including tile fixing, technical mortars and flooring systems, covering topics such as tiling on to underfloor heating, waterproofing and tanking, and levelling compounds.

Courses can be designed to meet product-specific requirements and to suit different levels of experience and skills.

James Mead, Technical Director of Saint-Gobain Weber, says: “We understand how important training is for the future of the construction industry and we tailor our courses to meet the ever changing requirements of the industry. Our aim is to bridge the skills divide by up-skilling our customers. And we continue to work closely with contractors to create specific courses to meet the requirements of their teams.”

For more information about the Technical Academy, or for product support, contact Saint-Gobain Weber on 08703 330 070 / technical.academy@saint-gobain.com. There is also a free Weber App for smartphone and tablet users available from iTunes and, for android and tablet users, Google Play.

Universeal

Rain-Off is a self-cleaning masonry, brick and patio sealer that is part of Universeal’s new Exterior Range. It is a water-based, synthetic resin emulsion general-purpose treatment to provide water repellency and stain resistance to external natural stone, masonry and concrete surfaces. Rain-Off significantly reduces the capillary water absorption of the treated surface without clogging the pores, allowing the surface to ‘breathe’ and transfer moisture vapour so there is less chance of efflorescence/salt blooming, organic soiling or moss and algae growth.

A sticky subject

Gorilla Glue is America’s biggest selling adhesive and now it is also taking the UK by storm for both trade and DIY.

Gorilla Glue is America’s biggest selling adhesive and now it is also taking the UK by storm for both trade and DIY.

Gorilla Glue will bond metal, wood, glass, ceramic and, of course, stone. Even with dissimilar surfaces it will hold firm, and it is waterproof and weatherproof.

It can be painted, stained and sanded for easy finishing. It can even be used in extremes of hot and cold.

Gorilla Glue is particularly effective for stone because it is designed to work on porous material. It penetrates to create an incredibly strong bond. One of its unusual properties is that it expands three to four times and develops into a foam, so a little goes a long way. When repairing with the glue it will penetrate to provide exceptional strength.

There are a number of Gorilla Glue products that work well with stone, including the original Gorilla Glue, Gorilla Grab Adhesive (for indoor, outdoor and even underwater use), Gorilla Super Glue (with a new nozzle) and Gorilla Glue Epoxy that sets in five minutes.

The adhesive market has sometimes suffered because of user confidence – or lack of it. Gorilla thought one of the reasons for this was the confusing and complicated messages incorporated into product branding and a lack of ‘how to’ information at the point of purchase.

So it has invested in education and combatting confusion with product demonstrations displayed on monitors at the point of sale. This is intended to end confusion and make it easier to decide which glue you need.

Gorilla Glue also provides its distributors with in-depth, one-to-one product training, giving staff confidence about how to advise the user.

And it provides additional support with glossy ‘Gorilla: How to’ guides, incorporating clear and concise descriptions and illustrations of how to use each Gorilla Glue product.