When you have seen the light you will never want to return to Correx. Digital templating is delivering significant productivity improvements to stone companies. Below is what some users of the Laser Products templater say about it.

Over the years, Kevin Massey, who works at Marble Building Products, Yorkshire, has tried a lot of different digital templaters. Now the company uses 12 Laser Products LT-2D3D units bought from Laser Products Europe, the company set up in the UK by Carl Sharkey in 2005 to distribute the American-made Laser Products systems across Europe.

Kevin says that since the introduction of the LT-2D3D four years ago he would not use anything else. “It’s so easy to use,” he says. “If I won the Lottery tonight and was foolish enough to start a granite company of my own, I would get the 2D3Ds straight away.”

Digital templating in general has come a long way since stone companies in the UK first started exploring it in the 1990s. It was not uncommon then for companies to give up on the idea and for units that had cost thousands of pounds simply to sit on a shelf gathering dust.

But processing power and speed has improved exponentially since then, making digital templating quicker, more versatile and a lot easier to use. CNC saws and workcentres are common in stone workshops, especially in worktop companies, and digital templating sits very comfortably with CNC machinery, making it easy to transfer the digital template to the machine using a DXF (Drawing Exchange Format) file that the machinery can use for sawing, routing and milling.

In fact, to use digital machinery, even physical templates produced in MDF, hardboard, Correx or anything else have to be converted to digital files. There are companies whose templaters still make physical templates and return them to the factory for digital templaters to be used to convert them into digital files.

Kevin Massey understands why. He says it takes time to build up confidence in digital templating, whereas a physical piece of board or plastic can be put on the kitchen units and if there are any errors they are immediately obvious. Customers also often like to see a physical template in place. It is something they can understand.

Kevin Massey understands why. He says it takes time to build up confidence in digital templating, whereas a physical piece of board or plastic can be put on the kitchen units and if there are any errors they are immediately obvious. Customers also often like to see a physical template in place. It is something they can understand.

But digital templating is a lot quicker and cleaner, both on site and in the factory, so unless there is some compelling reason to make a physical template, it is not something Marble Building Products does any more. However, the company does still insist its templaters check their figures against measurements taken by a rule, just to highlight anything seriously wrong.

Kevin says when there are errors the most common cause is that the tripod is kicked. Normally, when he is setting up in the first place, he puts three reference points on the walls, so if a passing plumber does accidentally kick the tripod it can be repositioned exactly where it was and the work can continue.

Just once, Kevin also forgot to tighten the unit on top of the tripod. If it is not securely fixed it can move on the fixing rather than recording the movement of the head. “I had put the head on the tripod, then the customer spoke to me. By the time we had finished our conversation I had forgotten I had not tightened it and started templating. It is the sort of thing you only do once.”

Before the launch of the LT-2D3D, Laser Products incorporated the Leica Disto with its system, which Marble Building Products used in conjunction with other digital templating systems and physical templates. But the introduction of the LT-2D3D converted the company to that technology exclusively.

Kevin says he has been in the industry more than 20 years and has a background in using CAD and programming CNC machinery. “I had 10 minutes on the LT-2D3D and I had got it.” It might take others less familiar with the technology or the industry a bit longer but they usually pick it up without too much effort. Since the launch of the LT-2D3D Marble Building Products' workload has increased so much that it has doubled its number of templaters.

And if any of them has not quite got it by the time they go out in the field, they can always call in for help. “I had a templater I took on last week. He was templating for a rectangular island with curves on it and he couldn’t quite get it right. From here in Yorkshire I was able to connect to his tablet and complete the job.”

The last of the company’s regions to get the LT-2D3D was Scotland, where the workload was slightly different and the two or three templates a week that were required were produced in hardboard. But since an LT-2D3D has gone there, templating has increased to two or three a day. “When you can, you do more,” says Kevin.

Kevin’s own personal best is templating 11 kitchens in a day, although he says it was for a plot so there was no travel involved. There were four pieces for each kitchen. He believes you could even do more than 11 a day if everything worked in your favour.

Marble Building Products is currently producing about 140 domestic kitchens a week plus commercial work of serveries, bars, floors, stairs… whatever is required. The company has three automated Breton saw lines, three five axes Breton CNC workcentres and four Comandulli edge polishers. Like many other companies, it has lately invested in a waterjet to help it with cutting the new generation of engineered products. Kevin says it has not had much problem with Dekton, but it has struggled to find the right approach for Lapitec and Neolith.

“Up until now the industry has not really needed waterjets and we weren’t sure whether we needed one or not,” says Kevin. It has, however, earned its keep and the company is now considering upgrading. Kevin favours Flow. “You won’t go wrong with Flow.” And, of course, DXF files from digital templates are used on waterjets, which are also computer-controlled.

As well as taking templates, the Marble Building Products templaters also take a lot of photographs on their tablets, which they transfer with the templates to the factory for production. A worktop templated this morning could be installed tomorrow, but that is not how it works because the design is usually sent off to the client for approval before the surfaces are cut (because as well as DXF files, the 2D3D can produce PDF customer reports and shop sheets). Turn-round time is usually a week.

The combination of digital templates and photographs is a highly effective way of avoiding disputes. The templates are accurate to ±0.0625in, according to the American manufacturers (that is about 1.5mm).

As most familiar with templating will be aware, sometimes the site conditions change between templating and installation and it is usually the worktop manufacturer who gets blamed if the worktop subsequently does not fit. Digital templates and photographs tend to end any argument.

Marble Building Products also asks its installers to take pictures when the worktops are in place, because it is surprising how often builders want to blame the worktop companies for any subsequent damage to walls or fittings.

“If it is our fault we’re there like a shot,” says Kevin. “If you say sorry and put it right quickly it goes a long way with the customer.”

Marble Building Products is possibly so happy with the Laser Products templater because it has been involved in its development. If there were aspects it had a problem with it would speak to Carl Sharkey at Laser Products Europe, the information would be fed back to the American manufacturers and if changes could be made, they have been. “When there has been anything we wanted to change we have usually found it is already in the pipeline anyway,” says Kevin.

“If there were any problems with the 2D3D now it would be that there could be a little bit more interaction with the software. I use AutoCAD and I like to be able to produce tangential arcs, which is too much for what the software on the 2D3D is designed for. It would be useful if there was an option to have more sophisticated software, but it depends how far they want to take it.”

On its website, Laser Products calculates the savings in time and materials of using its 2D3D system compared with cutting out physical templates. It says a physical template takes 7.5 hours to produce and a digital template 1.6 hours on average. It calculates the annual saving at $43,290 (£33,208). If you are cutting 35m2 of worktops a week, the 2D3D will have paid for itself in about four months.

Then there are also savings on transport because you can use smaller vans or even small cars to transport a digital templater and its tripod, which can make parking easier and minimise pollution charges in London and, increasingly, other cities. Some companies in London carry the digital templaters to site in back-packs on trains and underground. The laser unit, the targets it uses for marking the back edge of surfaces, and a tablet weigh 12kg and a tripod 5kg.

Recognised for consistency, reliability and performance, the LT-2D3D Laser Templator claims more awards than any other digital templator. Its honours include the 2015 Best Product at StonExpo and most recently it was one of this year’s Best of KBIS finalists.

Another of the many companies that have encompassed laser templating – and they include some of the biggest worktop manufacturers in the country – is LBS Stone in Storrington, West Sussex, which bought two of the LT-2D3D units about a year-and-a-half ago. Before that it had made physical templates, originally in hardboard, then in MDF and more recently in Correx.

Steve Cheshire, who deals with purchasing at the company, says the templaters and directors liked the idea of the use of lasers for the work. They looked at various systems and decided to go with LPE's LT-2D3D. It was a decision based on the people at LPE as well as the system itself.

"When we first got the LT-2D3Ds everyone was full of questions – can you do this; can you do that – and the answer was pretty much always 'yes'. Dean Bell from LPE trained us. He's a phenomenal guy. He knows everything inside out. If you get to site and you can't do something, nine times out of ten he is on the other end of the telephone and will say 'all you have to do is this'. But the software is so easy when you get your head round it. You only need the one day's training that you get when you buy the templaters.

"Last week we did a swimming pool – it needs 30 linear metres of bullnose copings." There was no water in the pool and the LBS templater simply set up the LT-2D3D in the middle of the pool and started measuring. "It was done in one-and-a-quarter hours," says Steve.

"Last week we did a swimming pool – it needs 30 linear metres of bullnose copings." There was no water in the pool and the LBS templater simply set up the LT-2D3D in the middle of the pool and started measuring. "It was done in one-and-a-quarter hours," says Steve.

LBS Stone is producing eight or nine domestic kitchens and bathrooms a day, plus commercial work (commonly restaurants). It works all over the country, and laser templating has certainly speeded up the process, especially when long journeys are involved, not least because the templates can be emailed back to the factory.

"It saves hours," says Steve. "We can be in Edinburgh in two hours. Gatwick is 17 miles north of us. You jump on a train and then get a plane. Two hours on site then catch the flight back at 4pm. The templater will be at the airport sending me the templates before he leaves. It used to take nine hours to drive to Edinburgh in a van with the materials for making templates then five or six hours on site templating. You had to stay overnight and the templates came back with the van.

"To take a template you set up the tripod, attach the laser to it, level it with a bubble on top, start the software and take the readings."

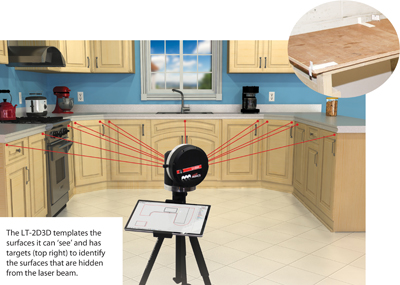

Targets are used to define the back edge of the template for the laser to read, as, naturally, it can only 'see' the front edges of units.

Once the template is sent back to LBS headquarters, Steve opens the files on his computer using software that comes with the laser templater and with just a few clicks of the mouse can make the adjustments that architects and designers always seem to want.

The 3D element of the LT-2D3D means the worksurfaces can be shown from any point in the room, which customers and designers often like. It also adds weight to any arguments about alterations after the templates have been taken.

Once the template has been produced, different pages of the software are used for different aspects, with the DXF files for the machines appearing as simple lines. In the factory, LBS Stone has two Intermac Master 33 workcentres and a GMM Brio profiler. It does not yet have a waterjet but it is on the company's shopping list.

Steve has been in the stone industry since he left school and he is now 49. He says: "I wish we'd had these years ago. This is progress. Once you've used these lasers you would never, never go back."