Software specialists Delcam, based in Birmingham, are showing the latest advances in the use of robots for machining at the Natural Stone Show (ExCel London from 30 April to 2 May).

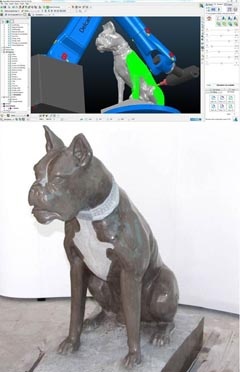

Recent developments in Delcam’s PowerMILL software mean that it is easier than ever to program robots for the manufacture of stone sculptures and other decorative items.

One barrier to the use of robots for machining was the cost and complexity of the software needed to program the toolpaths. Now, the new robot-machining interface in PowerMILL has made it far easier to program robots for a much wider range of applications.

And the ability to program the robot offline from 3D CAD data is both faster and more efficient than the 'teach and learn' approach often used to create instructions for the equipment. The programs can be simulated on the computer to ensure the results will be exactly as required.

This new programming method makes it easier to take advantage of the many potential benefits of using robots – namely, the cost of installation, which can be less than the price of a large machine tool with a similar working envelope, and the flexibility of the robot, which means complex sculptures can be completed in a single operation, reducing production times.

The best way to see the progress that has been made in programming robot arms is first-hand at the Natural Stone Show. Otherwise, contact Peter Dickin, Delcam's Marketing Manager, on +44 (0)121 683 1081.