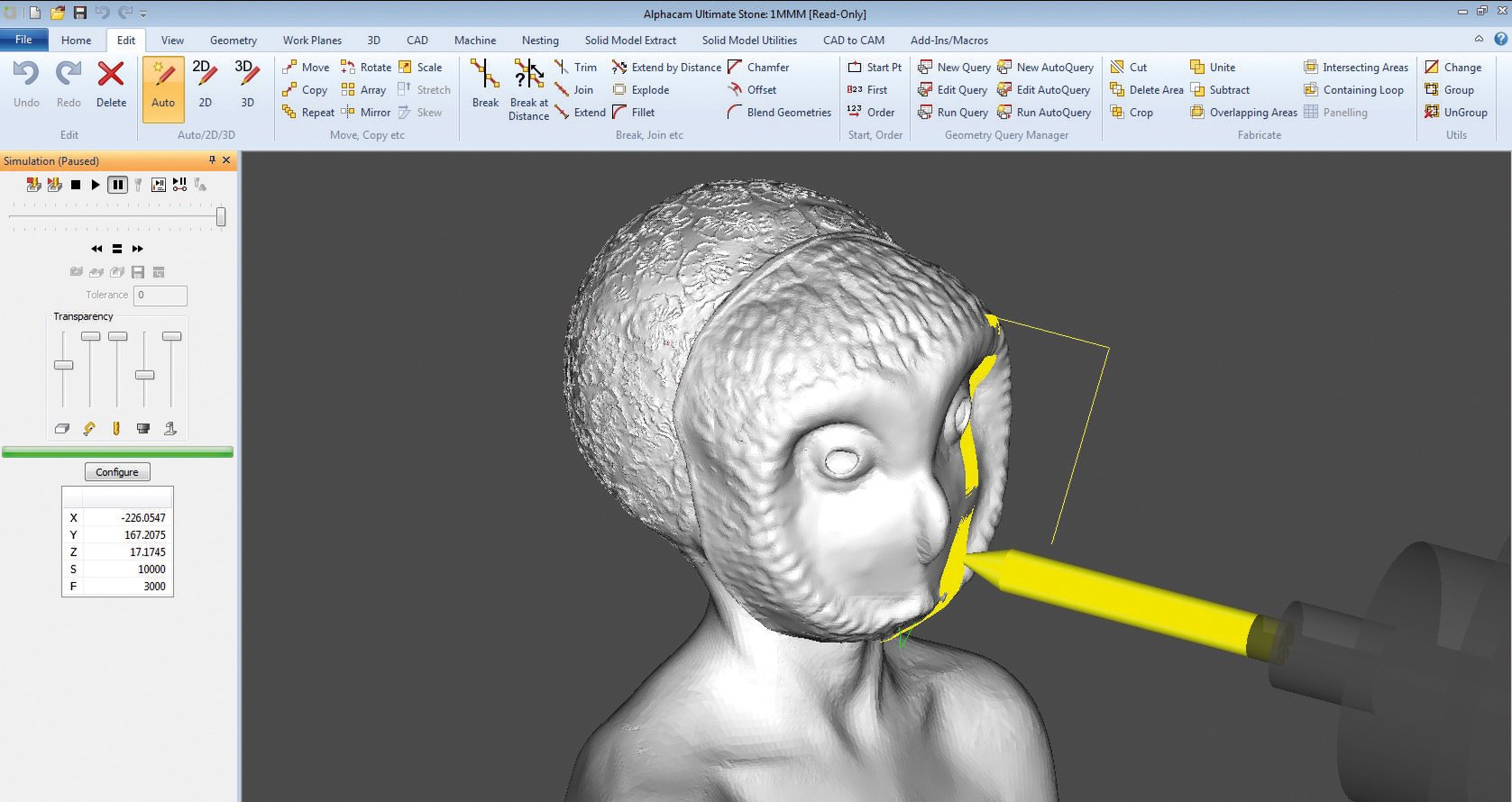

There is a new version of the Alphacam CNC stone machinery management software. It is called Alphacam 2020.0 and the company that supplies it says it includes even more best-in-class technology delivering major improvements that will deliver greater productivity, especially on five axes machines.

Hexagon Manufacturing Intelligence’s Production Software business that produced Alphacam 2020.0 is particularly pleased with the post-processor engine.

Brand Manager Hector Henry says the result is more realistic motion, as well as the ability to support cycles such as M6, and additional hardware that has previously been underused or ignored. “This new functionality is truly an industry-first and will surely become a new standard.”

The Automation suite has also been enhanced with new setup wizards making short work of daily production tasks.

There are two key new features of the advanced five axes functionality: one is the ability to integrate the toolpath optimiser into a core cycle which can be stored as a machining style and deployed with Automation; and the other is to include Barrel Mill and Double Profile Tools. Improvements in SWARF machining, multi-axes roughing and toolpath smoothing are also included. And the geometry offset command is now intelligent and dynamic, making all operations more productive.

A new feature provides a simple, productive and effective way to allow a user to define the order in which cuts will be made. Hector Henry says it now takes just seconds.

Full details of all the updates in this latest release of the software can be found on the Alphacam website.