There are already a lot of stone companies using Alphacam from Vero Software for CAD/CAM operations on their CNC machinery and there are likely to be more following the latest release of Alphacam that makes CNC manufacturing even easier and quicker.

Alphacam Automation Manager Plus includes enhancements to simplify the workflow, including multi-drill control, new styles functionality, and further support for additional CAD file formats.

The introduction of Automation Manager Plus across all levels of Alphacam allows advanced automation to support the processing of constrained drawings and parametric sketches, and part grain direction through sheet grain direction and alignment vector options. It also includes the cabinet door manufacture (CDM) module.

Alphacam 2017 R2 sees the first release of its integration with robot simulation software, meaning that output toolpaths generated within Alphacam can be passed directly to RoboDK’s offline programming (OLP) to simulate robot movements along with a range of applications and activities such as milling. RoboDK then outputs the OLP to the robot controller.

As part of the Vero customer experience improvement program, Alphacam integrates Microsoft Analytics to gather software usage statistics.

A new reverse cut direction option has been added to rough/finish and stone cut shape. Alphacam Brand Manager Simon Mathias says this is particularly useful when creating multiple passes around a shape that need to go in alternate directions, such as polishing and sanding profiled edges.

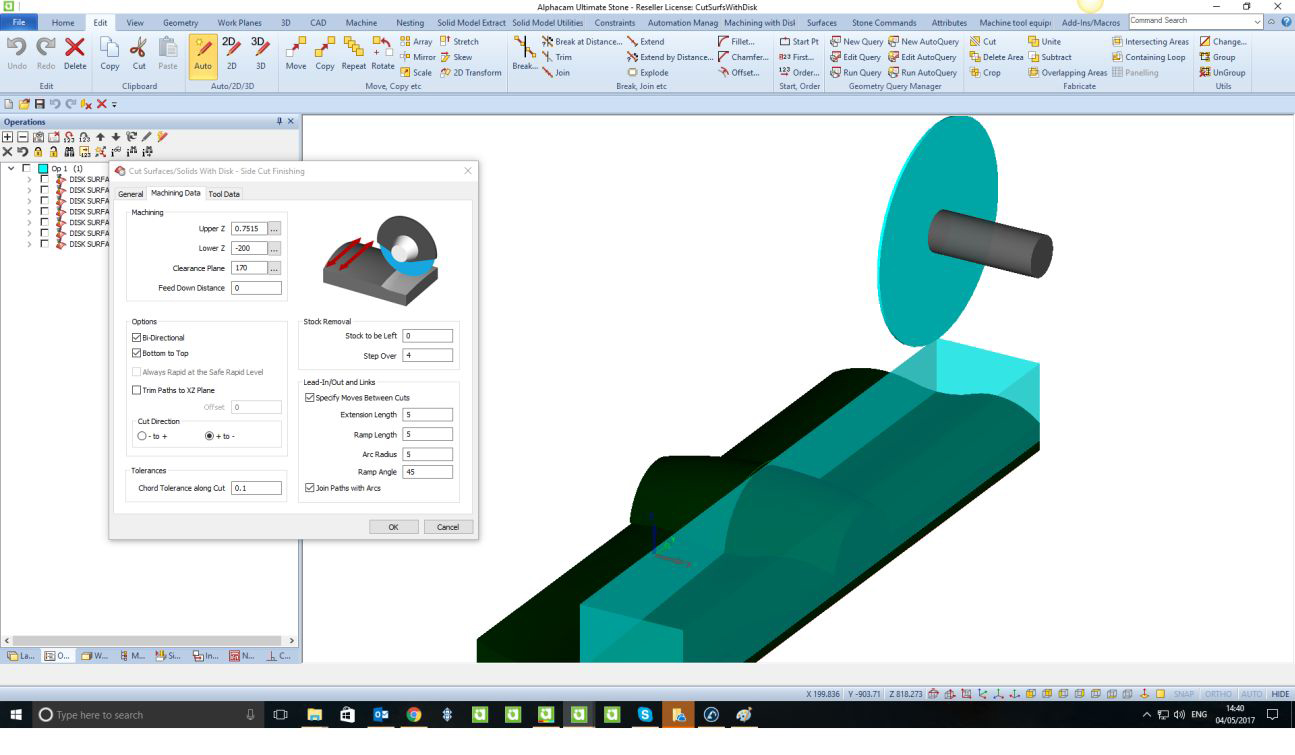

For Stone, Simon says cutting surfaces and solids with a disk has been made easier, as the user no longer has to create the work plane before starting. “The work plane can be created dynamically with on-screen feedback," he says. "Tabbed style dialogs have been introduced and all strategies have Extents visualisation of the area to be cut with dynamic cut directions and start positions.”

The Stone module now includes support for automatic detection of unsawn areas of the selected parts and the option to add a waterjet cut path operation with two new tabs added to the sawing dialog for the waterjet cut parameters and its lead in/out settings. “This is an essential addition to support the combination saw and jet machines in the market,” says Simon.

Sawing has been enhanced by controlling foul avoidance so it can be applied to none or all of the selected machining geometries. Foul avoidance geometries appear in a new branch of the operation tree, where geometries can be added or removed and the selection remade.

Support for 4K monitors has been improved with the addition of scaling options that make the icons larger for higher 4K dpi settings.

The input CAD extensions add-in now supports all imported file types. And the dialog will only be displayed if the CAD file imported something that can be processed. For example, at least one instance of geometry, text or spline.

There is a new tool for tidying up imported geometry from CAD formats such as DXF and DWG, where the designer may have created several overlays in design that are not required for manufacturing on a CNC.

In short, Alphacam 2017 R2 improves productivity and profitability by speeding up manufacturing processes.