Stone companies will find improvements for waterjet cutting and for sawing surfaces and solids in the 2020.1 release of Alphacam software.

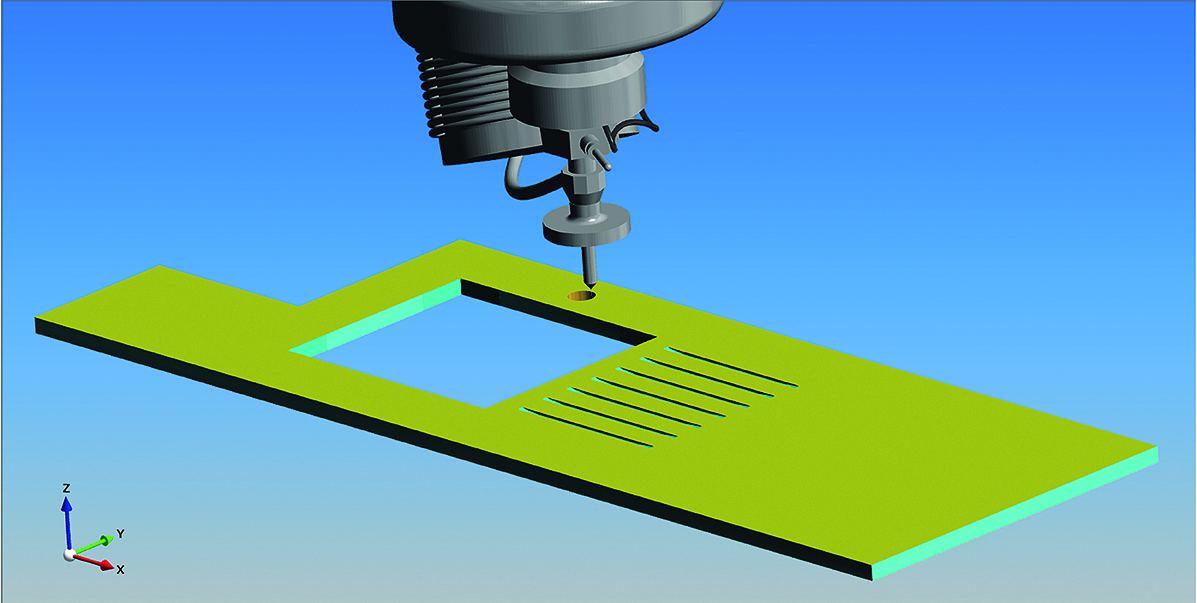

You can now create waterjet tools and specify parameters specific to waterjet cutting. Abrasive flow rates can be defined as well as how far the nozzle should be from the top of the material.

In addition to the existing machining cycles, Alphacam 2020.1 introduces three waterjet operations that can follow a profile, clear areas, or cut and pierce holes in both three and five axes machining. And to make sure everything is in order, a simulation can be run to check for possible collisions between the nozzle and the material being cut.

Product Manager Chip Martin says: “The software has been successfully driving waterjet and saw+waterjet machine tools for many years. But this new waterjet tool and cycles provide a consistent and highly professional way of calculating toolpaths.”

The new release also defines boundaries when cutting surfaces and solids with a disc. Multiple boundaries can be defined and Alphacam will avoid machining those areas.

“This gives much better control, making it possible to avoid areas that should be machined in another step, and even avoid other machine components,” says Chip.

At the same time a new job type is introduced. The ‘Multiple Process Jobs’ functionality makes it simpler to create jobs and orders in Automation Manager, which need to be output to more than one machine or require any secondary processing at the same machine.

“In the past, users had to create multiple jobs to process complex operations in Automation Manager,” says Chip. “But now a single job can be created containing all the different machines and manufacturing processes that the part goes through.”

The processes for the top and back of a part, for example, can now easily be worked as a single job. “NC code will simply be created for both of them automatically, which is also the case for additional machines and other processes.”

This improvement streamlines how complex manufacturing processes are handled in Automation Manager.

“Once the process is defined and the Multiple Process Job is created, the operator can easily repeat the same complex job many times for different parts. Also, the user interface will help show exactly which processes and machines the part will go through.”

Several enhancements have been made to Automation Manager’s output file options.

Firstly, the new File Name Configuration dialog creates names from job information, job files, or any custom text.

Secondly, a number of improvements to Report Creation include the ability to generate up to four different layouts, which can also be printed. All the materials being used can be included in one report; and a report can be produced for each material and each nested sheet.

“This fine-tune control means users can tailor Automation Manager output entirely to their specific requirements.”

The Rough/Finish of solid faces with Tool Side function now allows planar and cylindrical faces to be combined in a single selection. For solid faces that are perpendicular, or undercuts, an active work plane can be used to define the preferred approach angle (scanning direction).

“In the previous release we introduced the ability to machine solid faces directly for Rough/Finish and Sawing,” says Chip. “This has now been enhanced to allow simple planar faces to be machined without creating new geometry.”

Cylindrical faces can be selected, and Alphacam automatically determines the best angle for machining them while keeping a fixed angle for the tool in a work plane, so most controllers will be able to support compensation (G41/G42), and Lead-In/Out generated by Alphacam.

“Before this improvement, users had to carry out several steps to machine a selection of faces using the tool side. Now, instead of creating workplanes and extracting geometries, they simply select the faces for machining and Alphacam calculates the required tool angle and workplane to machine a selection of faces. This is a real time saver.”

NSS will present a case study from a company using Alphacam in a future edition of the magazine.