As Odlings look forward to a new Managing Director in Duncan Reynolds, they display their in-house artistic talents in a new brochure

The UK memorial market has changed unrecognisably over the years as manufacture has been ceded to the Far East. No wholesaler can ignore the price advantages of that. But by combining the manufacturing skills of the Far East with their own home-grown artistic skills, Hull wholesalers Odlings believe they have the best of both worlds. And they are showing off the results in a new brochure that is now with customers.

Two years in preparation, the brochure has stylish matt lamination on the cover and high quality photographs throughout. It features the work of their own creative team that have taken their inspiration from, among other influences, classical churchyard designs and added new features.

For example, a classic Norman round-topped memorial has had a moulding added to the front and back to give it a more slender appearance, while a rustic pitch-edged stone called the Etton incorporates a Celtic cross.

And there are the etched and painted decorations – now in patterns such as Celtic knots and oak leaves with acorns – for which Odlings are famous. They are available on all the company’s memorials.

The designs are created by Odlings, even though the memorials are generally produced in the Far East. The finer decoration is all added in Odlings’ own workshops in Hull by their team of artists under the direction of creative supervisor Alan Clough.

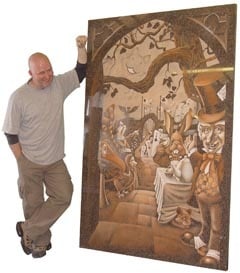

It was Alan who produced the Alice in Wonderland-inspired etched and painted granite motif that was on Odlings’ stand at the National Funeral Exhibition at Stoneleigh Park, Warwickshire, last year. He is pictured with it above. He says the team of five he has working with him are chosen on the basis of their artistic ability rather than their academic qualifications.

The granite carving of ‘Alice’ reading a book that was in front of the etched granite slab at the Funeral Exhibition was again designed by Odlings although the granite from which it is made was carved in China. It, along with a White Rabbit, is now in the children’s section of West Bromwich crematorium.

Odlings also showed on their stand the memorial designs that had been created for their new catalogue. They used the show to gauge the reaction to them by holding a competition that visitors could enter by filling in a form saying which they liked and which they didn’t. Chris Kemp, who heads the wholesale operation, used the market research derived from the competition to determine which designs to include in the new brochure.

He says: “We’re trying to get away from the norm. Anyone can buy ready-made memorials from China. We’re adding the design element.”

Odlings do still make memorials at their factory in Hull because some people want a memorial that is made in the UK or they want something sooner than waiting weeks for an import – and 75% of the memorials Odlings import are made to order and sold before the container arrives at Felixstowe or Southampton.

The price advantage of imports usually means people will wait, especially as the prices of memorials are currently under the same inflationary pressures as everything else.

Two years ago Odlings bought the land in Hull that their factory occupies and which they had previously rented from the council, but the cost of everything they use, from electricity and water to diamond tools, has increased. They have two lorries, one operating out of Hull and one from their depot in Bristol, that now cost more than ever to keep moving – they introduced delivery charges four years ago and have had to increase them this year. And the cost of shipping has increased nearly 40%, although it fluctuates a lot.

Even so, Odlings say they are selling more memorials than ever and their site in Hull has expanded over the years into neighbouring premises as they have become available to accommodate that growth.

But growth has not only come from memorial wholesaling. They also have a memorial retail business, called Crown Memorials, with seven outlets apart from the branch in Hull. Crown Memorials (North) shops are managed by Lee Hall. He says they are not actively looking for more outlets but that if the opportunity arises, they would consider it.

They have their own memorial fixers, all registered with Bramm. Lee has attended the Bramm training course himself. He describes it as “a very intense day” but well worth while.

In response to customer demand, Odlings are also now selling kitchen worktops locally, mostly through kitchen showrooms and fixers, although also to the public at retail prices so as not to compete with their trade customers. That means they now stock 20mm and 30mm granite slabs, which they also wholesale as raw slab to other companies in the area.

Like many memorial masons already geared up for working granite, the move into the fast growing kitchen worktops market was not too difficult a transition to make. In Hull, the floods of last year and the promotion of Hull City Football Club to the Premier League have helped to sustain demand for kitchen worktops.

Odlings’ entry to the market five years ago was accompanied by the purchase of a Seelbach semi-automatic worktop manufacturing machine that they have since replaced with a Breton NC250 CNC workcentre. They also have a Commanduli edge polisher and other workshop equipment at their factory includes Thibaut machinery that includes a T110 jenny lind, T612 edge polisher and T502 face polisher.

Chris Kemp is also in charge of the kitchen worktop side of the business, which includes a team templating and fitting. Having joined Odlings in 1989 in the workshop, Chris decided to go on the fortnight training course to learn how to use the Breton workcentre himself. It was more difficult than he had imagined it would be. “I aged 10 years. Then I had to show the others how to use it.”

He says CNC machinery in Odlings’ heated workshops is a long way from the sheds he worked in when he first joined the stone industry with a company called WGC. When he moved to Odlings, in winter they had to thaw the water pipes before they could start to use the jenny linds. But the better opportunities at Odlings were one of reasons he moved there.

Odlings are now selling five or six kitchens a week and have devoted a part of their workshops exclusively to this operation. They have also now converted the showroom to display worktops and have created an outside area to show the memorials. New signs welcome the trade and public to the ‘Stone Yard’ showroom to see the kitchen worktops and granite slabs on show.

Also under the Odlings umbrella comes the Columbaria Company, headed by Peter Roper, based at Odlings’ factory in Hull, who supply cemeteries with the carvings such as ‘Alice’ and ‘White Rabbit’ for children’s areas in cemeteries and cremetoria, as well as the columbaria for cremated remains. Peter says more cremated remains are stored in columbaria above ground these days than are buried.

Odlings are part of the Bridgwater Brothers group that has diverse interests including B I Crawshaw, the stone tool and consumables distributors, Odlings MCR, who sell blast cabinets and computers, plotters and masking for adding designs and lettering to memorials, Mill Hill slate quarry in Cornwall, Heirlooms, and Essex Flameproofing.

In charge of the whole Odlings operation is Managing Director Gerald Priestman, who this month (September) starts a year’s hand-over to Duncan Reynolds, grandson of the founder of the Bridgewater Bros group and son of the current Chairman, Chris Reynolds.

Duncan joined the family group in 2004 and has been running Essex Flameproofing. Before that he was in pharmaceuticals. Gerald started his 50th year with Odlings on 24 July, having joined the company when he was 16.

Duncan says of Odlings: “It’s got some fantastic products.” He praises the work of the designers and craftsmen at the company.