REPORT : Hard surfaces

New exhibition reflects barrier-free approach to design

A new exhibition has been launched called Hard Surfaces. It will run alongside the Natural Stone Show at ExCeL London 30 April to 2 May next year (2019). Here NSS looks at some of the product developments that have so expanded the hard surfaces market.

The options for horizontal and vertical surfaces in construction are increasing all the time. It is true of exteriors and interiors. Design is answering a host of aesthetic and practical questions using an ever growing range of ingenious products that expand the potential of the built environment.

Domestic interiors in particular have become major platforms for self-expression, and nowhere more so than in kitchens and bathrooms. Kitchens have become reception rooms where guests are entertained and families gather, while bathrooms no longer occupy the least possible amount of interior space but are areas for luxuriating in personal care and hygiene.

In commercial buildings, too, surfaces are designed not just to be practical and hard-wearing, but to make statements about the hotels and offices in which they appear.

This new appreciation of the style of essentially utilitarian space has developed in conjunction with a range of materials to create new looks.

There are solid surfaces such as the original Corian, which manufacturer DuPont introduced in 1967. Engineered quartz was added when stone machinery company Breton introduced the plant for making it, then in 1.25m squares, in 1979, although it is only in the new Millennium that it has become as popular as granite in the worktop market.

There have always been ceramic tiles, but as the trend for larger format slabs saw the rise in demand for natural stone that was available in this format, porcelain manufacturers responded by developing ways of making slabs of similar sizes.

More recently have come ultra compact surfaces, made by a process of sintering materials and then heating them and floating them into large sheets in the same way as glass is made.

Glass, too, has developed as a whole host of innovative products for horizontal and vertical surfaces, coloured and textured to excite innovations in design. Glass fibre and resin reinforced concrete has introduced an element of industrial chic to modern living. Classical terrazzo and mosaics are popular as the designs and materials evolve with innovative developments.

Nothing is exempt in the elevation of the individual stamp of personality. Even stainless steel, the preferred surface for many a commercial kitchen, is finding its way out into wider domestic and commercial interiors.

The development of these (and more) materials and their uses is tending to blur the lines between the different sectors of the industry. Stone companies are now starting to process glass (and vice versa) and some are thermoforming solid surfaces. And once a fabricator has moved outside their traditional comfort zone, they find it a lot easier to continue that diversification into other areas.

Solid Surfaces

DuPont marked the 50th anniversary of its Corian brand solid surface in 2017 with a new look, a new business vision that includes exhibiting at leading exhibitions and new ranges. The aim: to mobilize into a movement that takes the Corian presence in the design industry to a new level with a new generation of consumers, said Julie Eaton, Global Business Director for the Corian Brand.

DuPont marked the 50th anniversary of its Corian brand solid surface in 2017 with a new look, a new business vision that includes exhibiting at leading exhibitions and new ranges. The aim: to mobilize into a movement that takes the Corian presence in the design industry to a new level with a new generation of consumers, said Julie Eaton, Global Business Director for the Corian Brand.

DuPont has not kept the solid surfaces market to itself, of course. These days there is competition from companies such as Hanex, L G Hausy’s Hi-Macs, Samsung Staron, Avonite, Formica, Maia, Encore and more.

DuPont has not kept the solid surfaces market to itself, of course. These days there is competition from companies such as Hanex, L G Hausy’s Hi-Macs, Samsung Staron, Avonite, Formica, Maia, Encore and more.

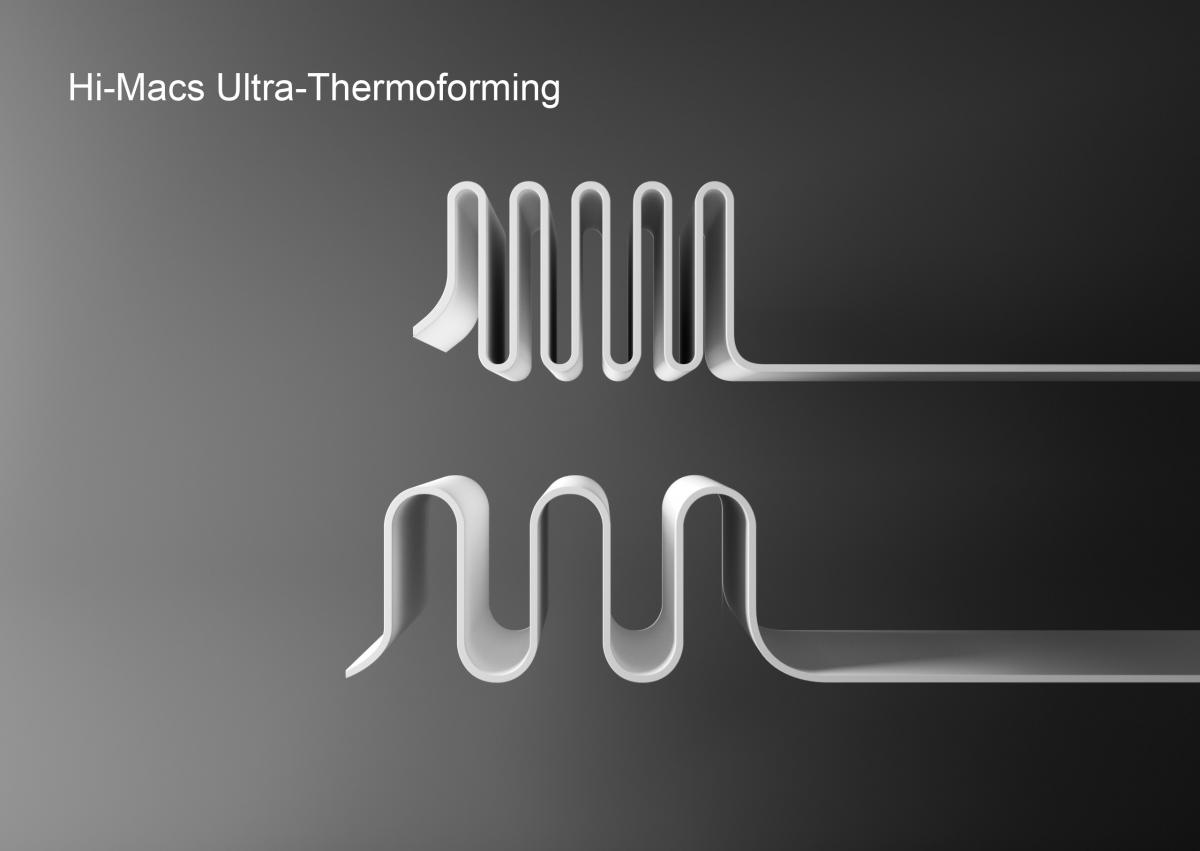

Lately, solid surfaces have started using acrylics rather than polyester as the basis for their fabrication. Polyester is less expensive than acrylic but the newer acrylic-based materials are generally considered of superior quality, although polyester is easier to thermoform (a method of shaping solid surfaces using heat). It is generally considered that polyester results in more vibrant colours when polished, but with a honed finish acrylics come into their own.

Engineered quartz

Engineered quartz is probably as familiar to most designers and householders as solid surfaces. Although it has been around a long time, the explosion in its use has taken place since the turn of the millennium. And it continues to take more of the market for worksurfaces in particular, especially from laminates. For some companies traditionally supplying granite worktops, quartz has taken over as the most commonly required material.

Engineered quartz is probably as familiar to most designers and householders as solid surfaces. Although it has been around a long time, the explosion in its use has taken place since the turn of the millennium. And it continues to take more of the market for worksurfaces in particular, especially from laminates. For some companies traditionally supplying granite worktops, quartz has taken over as the most commonly required material.

Quartz is strong, resilient and consistent. Because it is held together by resin it can be thermoformed, although this is not a property that is widely exploited. It can look convincingly like white marble, which is currently a popular look for surfaces in kitchens and bathrooms, taking over from blacks, and blacks with sparkly chips in them that marked the beginning of the rise of the popularity of quartz.

Silestone from Spanish company Cosentino is the market leader in the UK, but as sales have grown so have the number of brands. DuPont’s brand is called Zodiaq. Samsung has its Radianz. There are plenty of others – Caesarstone, Compac, Arenastone, Cimstone, Diresco, Hanstone, Okite, Quarella, Compac, Stone Italiana, Technistone, Trafficstone, Unistone and more. Some of the companies that sell quartz in the UK have created own brands, such as CRL Quartz from CR Laurence and International Stones’ iQ.

Engineered quartz contains a high proportion of natural quartz, finely crushed, mixed with pigments and other ingredients to create solid colours or patterns. It is all held together with resin but is typically more than 90% crushed natural quartz. The mixture is vibrated to remove voids then cured in heaters and polished or brushed to give it a smooth or textured finish.

Ultra Compact Surfaces

The latest development in hard surfaces is ultra compact surfaces (UCSs), as they are tending to be called. Most familiar are Dekton, Lapitec and Neolith. They are also sometimes called sintered products because they are made by sintering a mixture of natural ingredients (that is, squashing them together in a press) and then firing them in a kiln at high temperatures.

The latest development in hard surfaces is ultra compact surfaces (UCSs), as they are tending to be called. Most familiar are Dekton, Lapitec and Neolith. They are also sometimes called sintered products because they are made by sintering a mixture of natural ingredients (that is, squashing them together in a press) and then firing them in a kiln at high temperatures.

Like porcelain, they are tough and resilient. They are made in large sheet sizes so that horizontal or vertical surfaces made from them will have a minimum number of joints – or none at all in some cases.

Dekton, another product from Cosentino, has already been used as exterior cladding in the UK, notably at the 17-storey Vantage Point Archway Tower redevelopment in London. But it is more usually used for interiors. UCSs can be made in sheets of 20mm and 30mm thick, which is a popular worktop thickness when using granite. But they can also be thinner for lighter weight materials to adhere to walls as splashbacks and shower linings.

Because natural stone is often formed by the heat and pressure of the planet, usually over millions of years, the makers of UCSs liken their materials to the naturally occurring product, saying it has been formed by the same processes, only accelerated.

Cosentino says the development of the process for making its Dekton is an “evolution representing a technological and industrial leap capable of generating a new process, a revolutionary material and a leading product”.

Lapitec is described as a hard surface material that uses advanced scientific manufacturing techniques to create a product that is neither a natural stone nor an artificial quartz stone, nor a ceramic nor a porcelain, but which shares the natural advantages of them all.

UCSs can be made to look like many other materials, such as stone or wood, either by the choice of materials to form them or, like porcelain, by printing on the surface after the sheets have been manufactured.

Ceramics and porcelain

The difference between ceramics and porcelains essentially comes from the materials used to make them and the heat of firing. Porcelains would normally be made from finer materials that are fired at a higher temperature, which makes them stronger, denser and less porous. These are ideal properties for kitchen worktops, which is why they are becoming a popular choice in the KBB market.

The difference between ceramics and porcelains essentially comes from the materials used to make them and the heat of firing. Porcelains would normally be made from finer materials that are fired at a higher temperature, which makes them stronger, denser and less porous. These are ideal properties for kitchen worktops, which is why they are becoming a popular choice in the KBB market.

However, the terms ‘ceramic’ and ‘porcelain’ are sometimes used as interchangeable, and the materials used for worktops are the result of the advanced development of such techniques, applying technology used in the tile industry to create a product in dimensions that can be used for custom-made worktops, although usually thinner than stone, quartz or UCS (like ceramic and porcelain tiles).

Jetstone is one company offering these worktops and it now has more than 20 colours available, including metallic, rust and concrete. The company says that in view of the increasing popularity of this material because it is so practical, the range is only going to grow over the coming years.

Another version is the own-branded Ceralsio from CRL Stone, available in 27 colours and three thicknesses – 12mm for a slim worktop, 10mm for floor tiling and 6mm for wall cladding.

And it is not just in interiors that porcelain is taking market share from other products. It is moving outside into hard landscaping with products such as Talasey Group’s Vitripiazza and Vitrified Garden Paving from Marshalls.

Glass

Glass has only recently been introduced to the worksurface market but is finding no difficulty making an impression. Many designers have found it to be stylish, versatile and strong enough for use in contemporary design.

Glass has only recently been introduced to the worksurface market but is finding no difficulty making an impression. Many designers have found it to be stylish, versatile and strong enough for use in contemporary design.

Non-scratch glass worktops use a specially treated glass that is resistant to scratches that could result from the everyday use of worktops, even when coming into regular contact with metal utensils.

Again, glass is a material that is practically non-porous, is available in even larger sizes than most other materials, can be cut to just about any shape relatively easily, is hygienic and easy to clean, durable, heat resistant and can be coloured and decorated in any way you like.

Glass entered the KBB market primarily as a splashback but is developing rapidly now for other surfaces, both vertical and horizontal. It has, of course, been used in rainscreen cladding for many years and before that as glazing for centuries.

The glass used comes from a number of suppliers (Pilkington, St-Gobain, British Glass and others) and is manufactured into worktops by any number of companies processing it.

Terrazzo and mosaics

Terrazzo and mosaics have been used as resilient flooring solutions for millennia. The Romans walked on such materials. The actual products used these days have developed somewhat, but are still essentially cementitious (sometimes with resin) with stone (or other) incursions.

Terrazzo and mosaics have been used as resilient flooring solutions for millennia. The Romans walked on such materials. The actual products used these days have developed somewhat, but are still essentially cementitious (sometimes with resin) with stone (or other) incursions.

This is a specialist area and some of the companies working in it include Diespeker, Advanced Terrazzo & Tiles, Andrews & Sons, Agglotech, Quiligotti, Fegan Terrazzo and Zanetti. There are plenty of others.

Developments in this market have involved products such as Achtis Group’s Politura range of Microcement finished floors, designed to give an ultra smooth finish – and not just on floors, either. The material can be also be used for walls, stairs and worktops.

In Shropshire, TG Concrete – which is part of the Tudor Griffiths Group – has just joined forces with Concrete Polishing, from Oswestry, in a new polished concrete partnership.

TG Concrete General Manager, Dave Morris, says: “We’re always looking for innovative and creative ways to use our products and we’re delighted to be working with Martin Clark and his team to offer something very special to our customers.”

Another growing trend is the outside living room, separated from interior living spaces by bi-fold patio doors. Natural stone and porcelains are used to blur the divide, but terrazzo and polished concrete is another option.

Another company specialising in the design and creation of bespoke handmade, polished concrete surfaces using advanced cement formulas for interior and exterior use is Concreations.

Its polished concrete surfaces and products are designed to client specifications. They are a minimum of 40mm thick and can have a polished, silk or matt, ground (to expose the stones) or un-ground finish. They can include drainers, knockouts for sinks and hobs, hot plate / pot areas and personalised design details.

Haus in Nottingham create custom concrete interiors for clients throughout the UK and into Europe. Providing exclusive and bespoke designs to tailor every project to the individual requirements of customers

And Sustainable Kitchens in Bristol says concrete is a wonderfully versatile material for worktops. It says that as it is cast in a mould rather than cut from a larger slab, you can achieve shapes and forms that are simply not possible by sawing and routing.

Stainless steel

Stainless steel is the material of choice in many commercial kitchens. It is strong, durable, easy to clean and hygienic (because it is an alien environment for most bacteria to live on), waterproof, not affected by most foods and cleaning materials and capable of surviving extremes of heat. It is also lightweight.

Stainless steel is the material of choice in many commercial kitchens. It is strong, durable, easy to clean and hygienic (because it is an alien environment for most bacteria to live on), waterproof, not affected by most foods and cleaning materials and capable of surviving extremes of heat. It is also lightweight.

It has not tended to make the transition into domestic environments or front-of-house commercial applications because it has been considered cold, clinical and not easy to integrate comfortably into large areas because it can become overwhelming. However, designers are starting to see its potential as a feature on kitchen islands or small workspaces.

Making stainless steel worktops requires the specialist skills of companies such as Stainless Steel Worktops UK and Complete Catering Contracts. They are made to order and are not cheap. But neither are any of the products mention here. If you want a low price, there are still plenty of laminates available. But those who want to make an impression are extending their vision way beyond laminates.

By the time the Hard Surfaces exhibition opens it doors alongside the Natural Stone Show at ExCeL next year, there will already have been another year of developments to explore in this exciting, fast moving sector of the market.