Report : Water Management

Stone companies in the UK and Ireland are investing heavily in new machinery – machinery that uses a lot of water. Managing the supply and disposal of that water responsibly should not – and often cannot – be seen as optional.

There are still a lot of stone companies with rudimentary, home-made systems for supplying and disposing of all the water used by the machines they use to cut, mill, route and polish stone. It is not surprising because Directors tend to view water management as a cost rather than the investment that plant and machinery is normally seen as.

It surprises Stella Zambelis of machinery company D Zambelis, which supplies Omags, Terzagos and Achillis, among others. “People buy sophisticated machines but if they don’t have water the machines don’t work. Why people don’t care more about their water supply I don’t know.”

Recycling water and dewatering the sludge from machines has cost benefits – reducing maintenance of machines, increasing the life of tools, cutting the cost of waste disposal and using less water. But they are harder to appreciate than the instantly improved income delivered by a new CNC saw or workcentre.

Installing a water management system requires some consideration, not just of your current needs but also of your future needs if you want to avoid ripping it all out and replacing it in a few years’ time. You have to work out how much water you want to process, do you need a press, will you need a flocculant, what water pressure will you need, how will you get the water into and out of your factory.

However, water supply and disposal, as well as sludge disposal, are only likely to get more expensive as time goes on and environmental restraints get tighter. And as more machinery replaces people in the country’s stone processing workshop, ever more water is needed.

Typically, installing a proprietary water management system is put off until a company decides to invest in new machinery or build a new factory. It might well have to do something about the water in order to be able to get as much as it needs at the required pressures to its new machinery, so that is often when Directors address the issue.

It is made easier for them at that time as well because most of the companies that sell the machines in the UK also supply water recycling systems. – there is OMEC from New Stone Age, Turrini Claudio from LPE, Italmecc from D Zambelis, Martini Aeroimpianti from Waters Group, Fraccaroli & Balzan from Roccia Machinery and Miles Supply… They are all happy to work with customers to determine an appropriate system for customers’ current and likely future requirements.

Some of the biggest systems installed are from OMEC, supplied by New Stone Age to northern sandstone companies – companies such as M&M Yorkshire Stone at Bank Top Quarry in West Yorkshire.

M&M has many years of experience in natural stone quarrying and the processing of dimensional stone and has lately put a significant injection of capital investment into hi-tech computerised equipment as part of its ongoing improvement strategy. That has included two new Super 800 Monoblades from BM and a BV-Tech ashlar line, both manufacturers which New Stone Age also represents in the UK. M&M says its investment has prepared it to meet the increasing demand for everything from rough block to fully architecturally masoned stonework.

With the new machinery it has bought came the new OMEC water treatment plant. It has a OMD60 M H2O combined water treatment and storage silo capable of treating up to 1,400 litres of water a minute. The silo has a capacity for 60m³ of combined water treatment and storage. James Turton, MD of New Stone Age, says: “Normally we would use an OMD30 (30m³) for treating 1,400 litres/min. But because we also helped design and specify the pipework around M&M’s building, the clean water is gravity fed to the saws, removing the need for clean water pumps. The OMD M H2O Silo is 12m high, which provides 1.2bar pressure.”

Machinery makers normally suggest water should be at 2bar minimum, but because the OMEC system has been designed individually for the application it has been possible to ensure correctly dimensioned pipework will deliver stable pressure at all times, so 1.2bar is more than enough to ensure the machines have adequate water.

“We have made sure the safety pressure switches on the machines work correctly. Indeed, we have not had to fully open the main clean water feed valve from the silo,” says James. “The customer is very impressed by how much pressure and volume is generated.”

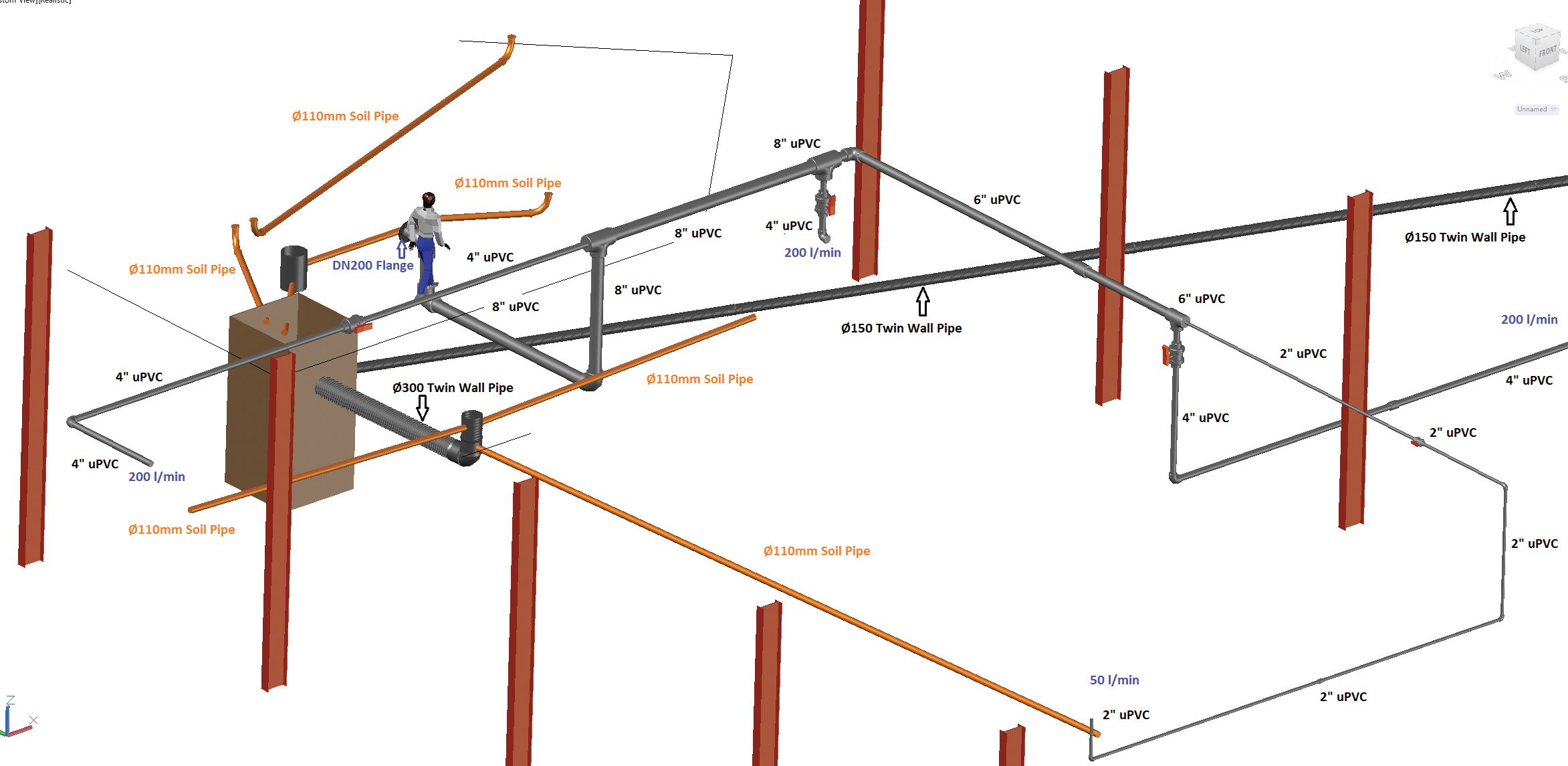

This is anything but guesswork. New Stone Age provides 2D and 3D drawings to the customer (an example of one of the 3D drawings is at the top of this page) showing the design to help install the complete Water Delivery System to the machines. This includes specifying all the return pipes for the waste water returning to the well.

The M&M system includes a filterpress, which is an OMF814 HT (High Tech) that comes with fully programmable PLC touchscreen controls that allows a working schedule to be set throughout the week. Most filterpresses only need to start pressing later in the day when the mud starts to build up in the Silo. A customer who works 5-6 days a week might program the filterpress to work Tuesday to Saturday (11am-6pm), for example. The touchscreen also has fully interactive fault finding and maintenance schedules, showing photographs of the parts affected for identification purposes if a problem arises.

Another OMEC system is currently (November) being installed at Dringstone Ltd, in North Yorkshire. It includes an OMD30 silo, plus an OMT30 storage silo and an OMF814HT filterpress. “This is our most popular system for medium-large factories,” says James. It treats up to 1,400 litres/min, which could have been accommodated by a combined treatment and storage silo, but the height is restricted so a separate storage silo is being used.

And just a warning from James: flocculents used to settle the solids out of water in the silo can result in corrosion by electrolysis, so silos should be earthed.

Most stone processors do not need systems of the size of the OMECs mentioned above and a lot can process sufficient water with bag filters like those pictured left in the system from Turrini Claudio that LPE Group sells along with its Breton and Comandulli machinery.

It can be fitted with a press, but LPE Director Simon Bradbury says if you use the correct bags the mud dries out quickly and is easy to dispose of in the bag. To make the water even cleaner it can be passed through a 10-15 micron filter in a stainless steel pressure vessel.

Typically, the 500 litre/min DP500 will suffice, or perhaps the 800 L/min DP800. They have an integrated flocculent system but Simon believes people often use more flocculent than they need to, probably at the suggestion of the chemical company that supplies it. “Most people only need a capful a week,” he says.

Normally the customer prepares everything, including 75mm plastic pipes for delivering clean water to the machines and a concrete base to take the silo (as the DP500 holds 22tonnes of water) and connecting it all up takes less than a day.

LPE has supplied 12 of the Turrini Claudio plants in the past year and has orders for seven more. A fairly typical customer is Rock Revelations in Kettering, Northamptonshire, which has bought a DP500 to replace an earlier 200 L/min system. The company has a Denver Slot and Skema Logic, a Breton Smart Cut, a Comandulli edge polisher and two Intermacs, a Master 33 and a Master 23, which it says are often all running at the same time. The next anticipated investment is a waterjet cutter.

Rui, who works there, says it is easy to use and four months after it was installed the two filter bags and just needing replacing.

The company did not take the option of the additional filter for its CNC machines because it was an extra £2,000 that it did not want to spend, so it supplies the spindles with clean water from a separate source.

The reluctance to spend more than necessary on water treatment is understandable but misguided, according to Stella Zambelis, who encourages the customers who buy the Italmecc system she sells to spend an extra £2,000 on it to future proof it rather than having to buy a new system, which is a lot more expensive.

It is an argument she is clearly making successfully because the latest six systems she has sold have included the adaptation, which simply upgrades the control panel.

This provides for a polyamine to be automatically added if necessary. Stella says that the provision for adding polyamines can increase the processing ability of a system with a 4,000 litre silo from 120 L/min to 300 L/min and produce exceptionally clear water.

Thanks to a new feature that became available this summer, Stella also recommends her customers have two inverter pumps, one 2kW and the other 4kW, to save energy. The Italmecc will use only as much power as it needs to supply water to the machines that are actually running. If no machines are being used, the pumps are not working. If the 2kW pump can provide enough water, it will operate and the 4kW will stay idle.

Neil Formby of UK Ceramics & Stone (also trading as Weybridge Granite & Marble) in Addleston, Surrey, bought an Italmecc water treatment plant from D Zambelis at the same time as he bought a new Terzago bridge saw to accommodate an order for 220 vanity tops and bath panels. “We just didn’t have enough water,” he says. “The silo gives us six or seven times the water supply we had before.”

He likes the fact that the pumps only work when his machines need water and only supply as much water as they need – they produce a pressure of 3.2 bar. He also likes the fact that it is no longer necessary to have two of his employees spending a whole day cleaning the mud out the settlement pit every time it fills up. “It will save us money in the long run,” says Neil.

The water from the machines is collected in channels 500mm wide and 600mm deep that Neil employed a contractor to cut into his workshop floor. He also had to install a 63mm water supply pipe and a power supply for the Italmecc in the yard, but getting the system in, up and running was quick and easy and, as Neil says, he could not have run his machines without it.

Waters Group is another of the machinery companies offering water management solutions along with the Cobalm CNC machinery, Montresor edge polishers, Flow waterjets and other machinery it sells. It has represented Martini Aeroimpianti in the UK for more than 10 years. Its customer Phil Battersby from Everything Stone has written his account of his choice of water treatment on the left.

Martini has a range of systems that can supply from 120 litres/min up to 1,200 litres/min as standard units. The majority are sold with a bagging station for the collection of the waste, although Waters says a few customers lately chosen the filterpress option, which dewaters the waste and compacts it.

The Martini Aeroimpianti Lindo water treatment systems have a laminar pack which speeds up the process of separating the waste from the water with no flocculent needed for most customers. And the laminar pack inside the Lindo is now made from Nylon, which is resilient to degradation.

All the pumps have ceramic seals to prolong their lives.

Case study

Everything Stone starts as it means to go on with a bit of help from Waters Group

This year, Everything Stone in Par, Cornwall, decided to stop buying stone in from other masonry companies and open its own workshop instead. It was a major step for the company. Here, Director Phil Battersby explains the move and why he chose to start off by including a Martini Aeroimpianti Lindo 200 water treatment system as part of the package from machinery supplier The Waters Group.

This year, Everything Stone in Par, Cornwall, decided to stop buying stone in from other masonry companies and open its own workshop instead. It was a major step for the company. Here, Director Phil Battersby explains the move and why he chose to start off by including a Martini Aeroimpianti Lindo 200 water treatment system as part of the package from machinery supplier The Waters Group.

Why did we decide to start manufacturing? We’ve been templating and installing stone worktops for approximately eight years and we’ve tried everything we can to get more involved with kitchen studios, designers and building contractors. And although we have forged relationships with some companies, we have always struggled with being competitive and have lacked the ability to accommodate a quick turnaround.

The manufacturer that we have been using is based in Swindon and while they have been great over the years, you can imagine that driving up to Swindon from Cornwall once a week to collect worktops has taken its toll.

Being independent has been our goal for a few years. We wanted to offer our customers better prices and be competitive, but we also wanted to offer our customers a better experience when they visited us. Purchasing worktops for a lot of customers is like buying a car – it’s quite an expensive one-off purchase. So being able to show the customers large slabs of granite, right next to a fully equipped workshop with the latest CNC machinery was key to our development as a business.

For us, the purchase of the machinery was always going to be difficult. We knew we had to box clever with finance and so we set out to obtain grant funding for our deposit. That was a long journey.

We set ourselves three steps to achieve our goal. The first was ISO accreditation, and although this wasn’t a necessity from a finance perspective, I felt the processes that ISO helps companies like ours implement would massively benefit us as a business, especially before we started to manufacture.

The second step was to find a suitable workshop. The perfect solution presented itself when a building became available on the same industrial estate as were already on. It was literally right in front of our current showroom, so we bit the bullet and snapped it up some 18 months before the machinery arrived.

Step three was to obtain grant funding and asset finance, which although at first was a very long winded and difficult process, became much easier when I was introduced to Close Brothers Finance.

Having completing these three steps (which took approximately three years!) we could finally start with the best bit – choosing machinery. With The Waters Group down the road and the fact that we have been buying from them for a number of years, it was a no brainer.

Daniel Waters has always been on hand, always happy to assist and is full of knowledge about the stone industry, which was essential for us. We needed assistance from a company that was there to help. And I feel that Waters aren’t just a supplier, they really did help us understand what machinery we actually needed rather than just selling us the biggest and most expensive.

They helped us purchase the machinery that was perfect for the size of business we are as well as future proofing us for the next few years as we grow. This is why we chose the Cobalm Idea Integra 5axes CNC bridge saw and Cobalm Idea Top CNC routing centre.

We increased the size of the tables of the Integra and Top to allow us to accommodate the largest slabs of granite and also increased the size of the blade housing on the saw so we can cut stone slabs up to 225mm thick, which will help when we start manufacturing more architectural stonework next year, as we plan to.

We also purchased a Martini Aeroimpianti Lindo water recycling plant from The Waters Group. We felt this was important because we wanted to start as we mean to go on and recycling water is the right thing to do with the amount that our new machines would required every day.

We also purchased a Pillar / jib crane with pneumatic lifting equipment to help move the worktops effortlessly, reducing the risk of breakages and accidents. Waters have also supplied all the consumables, tooling and materials required for manufacturing, templating and installing the worktops we are now making.

So, with the stone machinery selected and finance sorted, we started to carry out the necessary renovation works in the building to create our new workshop. It basically involved erecting a two-storey building inside the existing building. This enabled us to create two offices, crib room, shower room, wet cutting / polishing room and a drying room where the worktops could rest before being sealed.

The workshop was in quite a state when we took it over and we wanted to create a nice working environment, so we spent many evenings and weekends preparing the building. We carried out all the building works ourselves, which included the installation of linear drainage channels, water catchment tank, clean water tank and water recycling plant, pipework and water filter, air compressor pipework, installation of the jib crane foundation base and all other items.

We started out as a building company – my brothers and I have been building since each of us left school – so we were able to do all the building work ourselves. I specialised in ground works, civils and hard landscaping, my brother Alex specialised in Carpentry and my other brother, Ross, in stonemasonry and hard landscaping.

When we had made all the alterations and decorated the new workshop to our satisfaction we were ready for the machinery to be delivered. By the time it arrived with us at the end of July we were just about ready. The Waters Group arranged for two engineers to assist with the installation of both the CNC machines and provide training, which was imperative for us. We took delivery of our first batch of stock – large slabs of granite, marble and quartz – and got right down to manufacturing.

We always have had a steady flow of enquiries but now we are more competitive we have started winning more work straight away. We immediately became fully booked up and continue to be so, even though we have just taken on our second employee since purchasing the machinery. We still find ourselves becoming busier by the week.

We feel we have made the right decision to start manufacturing and are happier as a business. We now offer our customers a much better experience when they visit us and, most importantly, we are more price competitive.

The future is looking bright!