James Simpson, OBE, Hon DSc FRIAS, Consultant to Simpson & Brown Architects and Chairman of the Building Limes Forum, speculates on new structural roles for natural stone and lime mortars in a more environmentally benign system of post-modern construction.

In the 21st century the structural use of stone tends to be limited to the context of conservation. Even in repair and restoration work it is often only to reinstate the appearance of a façade that decayed ashlar blocks are replaced with new matching indents.

In old stone cities like Edinburgh new office blocks are finished with stone ‘wallpaper’ cladding to help them fit in, and all over the country housebuilders offer ‘appliqué’ panels of rubble to give ‘character’.

This is a cruelly harsh view of today’s stone industry and, of course, it tells only a small part of the story.

Quarrying from Portland on the coast of England to Caithness in the north of Scotland continues to produce magnificent natural stone that reflects the complex geology of the British Isles.

While the industry is highly mechanised, the old skills of riving with plugs and feathers, docking and splitting survive.

The best machine shops are well set-up for primary and secondary sawing, planing and polishing, while the expertise of the good banker mason in working with hand tools to boast, dress, stugg, drove and broach is as highly valued as it ever was – if not so widely.

There are first class building masons all round the country, working with new and re-used stone to build new walls and repair old ones, preparing and using lime mortars for bedding, pinning, packing, finishing and pointing wall surfaces.

In the pre-industrial age, stone was valued less for its aesthetic qualities as for its usefulness as an everyday structural material that could carry great loads.

Edinburgh’s tallest tenement, rising to 12 storeys, was built in 1690.

The masons who built the medieval cathedrals exploited the compressive strength of stone to an extraordinary degree. The way they used columns, vaults, arches and flying buttresses to enclose massive and complex volumes while avoiding tension was highly sophisticated.

They understood very well stone’s lack of strength in tension. Lintels were treated not as beams but as flat arches, packed tightly at the ends, sometimes even voussoired and often helped by more or less formal relieving arches above them.

Traditional use of stone

These traditional stone structures were built with lime mortar. It was permeable, sufficiently strong in compression but even weaker than the stone in tension, which is ideal for a mortar.

Wall surfaces were commonly brought to a flat face to minimise the surface area and avoid water-holding ledges. Or they were protected and decorated with lime plaster or limewash to an extent that is neither recognised, except by a few archaeologists, nor widely understood today.

Distinguished architect Robert Adam and his brothers used to refer to their mason architect father, William Adam, as ‘Old Stone & Lime’. For thousands of years natural stone and lime mortars and renders have been inseparable.

In the areas where stone was quarried, buildings were constructed of stone and lime, and their surfaces were commonly decorated inside and out.

The appearance of the stone wasn’t seen or valued in the modern way. It was often covered with lime plaster and white or coloured limewash. Sculptures would often be painted.

When tensile members were required in traditional building, mainly for floor and roof structures, the available material was timber. In the Middle Ages it was generally native oak. As building increased in the post-medieval period, pine was brought in sailing ships across the North Sea from Scandinavia and the Baltic.

Stone, lime and timber, assembled with labour and skill, were perfectly complementary. They were low energy and low carbon, and produced buildings that were maintainable and sustainable.

Despite common assertions today, they could – properly managed – be economical of heating energy in use.

With routine and timely maintenance their life was indefinite. They were easily improved and re-purposed and, if they became terminally redundant or had to be replaced, their components and materials were easily re-used or recycled.

Most importantly, and something which has tended to be forgotten, ‘traditional building’ was a system that depended on materials being relatively soft, weak and flexible to accommodate movement, both of the ground and of the building materials themselves. They were also permeable and made use of primary and secondary ventilation.

With the industrial revolution, everything changed. First cast iron then steel, Portland cement mortar and concrete, and, more recently, plastics produced what we now recognise as ‘modern construction’.

Engineers of various sorts became pre-eminent. Steel and concrete frames superseded loadbearing masonry walls and building envelopes became impervious, insulated skins faced with metal, glass, plastic or stone, the selection of which, along with overall shape and interior design, remained within the limited province of the architect.

‘Traditional building’ and ‘modern construction’ are entirely different systems. Modern construction depends on materials that are hard, strong, inflexible, impermeable, processed and assembled with the aid of machinery with as little labour and skill involved as possible.

Unmaintainable

While often being described as ‘maintenance-free’, it would be more accurate to describe much modern construction as ‘unmaintainable’ in the normal meaning of the term.

When key components like plastic windows fail, as they do, they have to be removed and replaced. While large open plan spaces may be flexible and capable of being ‘re-purposed’, it isn’t easy, for example, to convert deep-plan office floors into apartments for living in.

The life of such buildings is distinctly finite. And when they are demolished few of their component materials are re-usable or re-cyclable. Most are fit only for landfill.

The mixing of these two systems of construction has created more problems than it has solved – something which has had to be learned the hard way.

The application of Portland cement mortars and renders to traditional buildings, the insertion of damp-proof courses and membranes of various sorts, and the restriction of ventilation has created condensation, dampness, efflorescence and rot, all of which had previously been familiar only as symptoms of maintenance failure.

The treatment of wood-rot with toxic chemicals and the growth of the so-called remedial treatment industry were disastrous consequences of short-term thinking and a failure to understand traditional building as a mature and highly developed system.

Sadly, this sort of failure was all too common in the 20th century and the climate-change crisis is one of the results.

Construction world-wide, and the manufacture of cement and steel in particular, are massive consumers of energy and emitters of carbon dioxide into the atmosphere.

Reversion to more benign forms of traditional building might seem to some to be desirable but, except on a tiny scale, is clearly romantic nonsense.

The replacement of traditional building by modern construction was a logical progression and time does not go backwards.

What is required in the first half of the 21st century is a new form of post-modern construction, relevant to contemporary needs but as sustainable and as environmentally benign as pre-industrial traditional building used to be.

Lessons could be learned from the past, even though there can be no going back. Such a system of construction might be more expensive in the short term, but could still be cheap at the price.

The extent to which modern economies have been built on energy from fossil fuels is too easily forgotten. The resulting prosperity has brought great benefits of many sorts but has stored up equally great problems for the future. The impact of modern construction on climate-change may be as great as that of the internal combustion engine. The generation of energy from renewable sources will be part – but only part – of the solution.

It does not make sense today to quarry limestone, burn it with aluminium and a few other ingredients at extremely high temperatures to create a powder that is mixed with water, sand and gravel to convert it back into a solid material. And concrete is not good in tension. It has to be reinforced with steel in order to build with it.

Could there be an opportunity for the stone industry to develop new ways of using stone structurally?

Engineered stone

The term ‘engineered timber’ is already commonly used in construction, so why not a structural ‘engineered stone’? Not engineered stone like resin quartz, which is crushed stone glued together with resin. Nor so-called sintered stone, which is crushed stone mixed with other minerals, compressed at high pressures and cooked at high temperatures. But rather natural stone engineered into structural building components.

Could it become possible to create sophisticated buildings to suit contemporary needs from more local, more natural and less processed materials?

Such a new post-modern system of construction could produce the loose-fit, low-energy, long-life principles proposed by RIBA President Alex Gordon in the 1970s – and ignored ever since!

The result could be buildings that are flexible enough to be re-purposed rather than demolished when needs change. They could even be capable – like the new Triodos Bank Headquarters in the Netherlands – of being dismantled and all their components and materials re-used or recycled.

The worst thing for stone – and for bricks, come to that – is for them to be bedded, jointed or rendered with hard cement mortars.

The purpose of mortar is not to stick masonry together but to keep it apart, avoiding point contact and distributing compressive loads evenly.

Lime does that so much better than hard cement, as well as having much less embodied energy than cement and being capable of re-absorbing carbon dioxide emitted in the making of it.

However, the most important reason for preferring lime to cement and concrete is that it facilitates re-use and recycling.

The most exciting possibility for the stone industry, though – and a challenge being thrown out in this article – is the possible creation of a system of engineered stone for framed, or partly framed, structures.

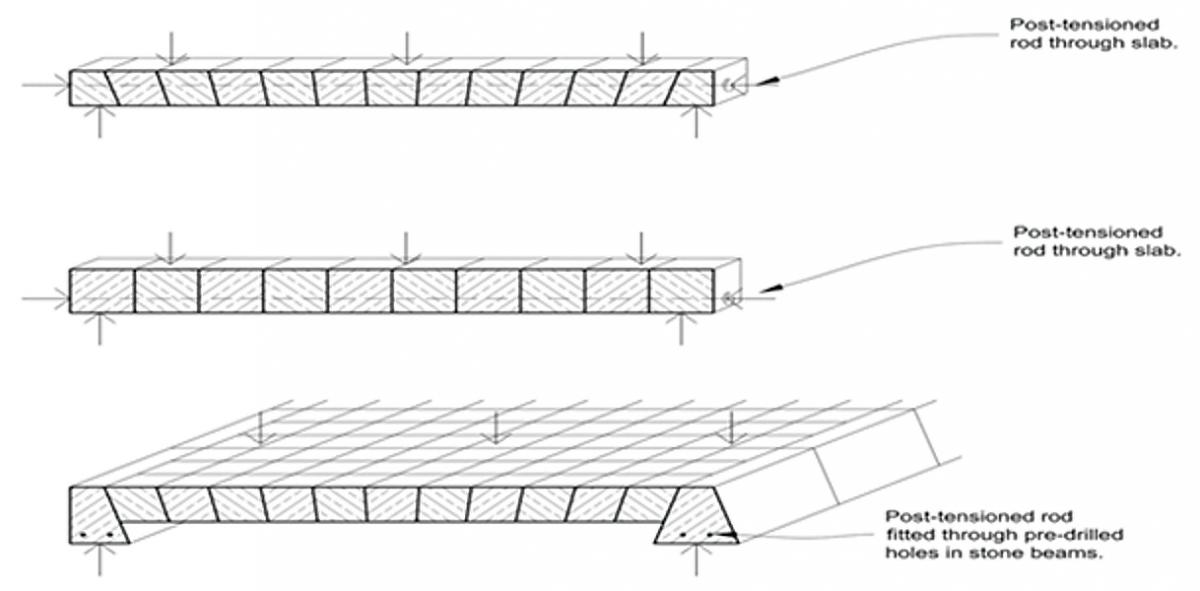

This would exploit the compressive strength of stone, which can be greater than that of concrete, combined with post-tensioning by stainless steel rods.

Walls, columns, beams and slabs could all be made from small pieces of factory-sawn stone, cut and pre-drilled to a design of standard components.

The basic principle for spanning elements would be that of the post-tensioned flat-arch or lintel, though (probably) in the interest of component standardisation without the need for voussoiring.

This notion should not be quickly dismissed as being impractical and uneconomic. It’s a kite worth flying.

There is no doubt that climate change will have (indeed, is having) consequences for construction. The government wants carbon-neutral construction and architects are keen to deliver it. A group of them last year formed the Architects’ Climate Action Network (ACAN) saying architects are not acting with anything like the urgency required to address this problem. In June, RIBA published its Climate Declaration, when RIBA President Ben Derbyshire said: “The climate emergency is the biggest challenge facing our planet and our profession.” He said: “...we need to turn warm words into impactful actions.”

One of those actions will have to be favouring low-energy, low-carbon, natural, local and unprocessed materials. Natural stone and lime mortars fit the bill.

In the inevitable drive towards more environmentally benign ways of building there will be less use of cement and concrete, greater use of lime and a substantial new role for natural stone, which remains a great national resource.

Post tensioning

Stone is strong under compression. The compressive strength of a sedimentary building stone is usually in the order of 40-50N/mm2, sometimes a bit more. Applying tension using a steel rod would be unlikely to exert more than 5-10% of that, rising to perhaps 20% with the application of lateral loads.

Post-tensioning of stone was developed in 1927 by Eugene Freyssinet, a French engineer. He saw pre-tensioned reinforced concrete beams being made by pouring concrete on to steel under tension. This gives them great strength when lateral loads are applied so they can be used as lintels or beams without cracking or breaking. It is a process still used today.

Freyssinet realised the same principle could be applied to stone by applying the tension after steel had been threaded through a hole drilled through the stone (hence post-tensioning as opposed to pre-tensioning).

The benefit of adding tension to the stone is that it makes it more capable of supporting lateral loads (from roofs, for example), so slimmer sections can be used than would be necessary without tensioning.

It also means finished components are manufactured off-site and can be installed quickly when they arrive on site.

Although the concept of post-tensioning has been around a while, its use has tended to be restricted to landmark buildings with load-bearing stone elements.

The Michael Hopkins Partnership notably used the process in 1995 for the 28 Ketton limestone columns that hold up The Queen’s Building at Emmanuel College, Cambridge. The columns were made by Ketton Stone. Without tensioning, the slender columns would simply be pushed out by the weight of the roof.

Five years later Michael Hopkins used the system again for the Birchover sandstone and DeLank granite columns on Portcullis House, the new parliamentary building in Westminster.

In 2009 architect Barry Kendell from the practice of Sheppard Robson was keen to use stone on the new build element of the redevelopment of No1 Southampton Row in the Bloomsbury Conservation Area of London. However, he also wanted the floor-height mullions to be elegantly slender.

To satisfy both requirements, the stone was produced as post-tensioned columns of Cadeby limestone. This had the added advantage of speeding up the construction on site so the stone was installed in just three weeks rather than the eight weeks it would have taken to hand set. The columns stand on transoms of the same stone that transfer the weight back to the floor plate via corbel plates.

Structural stone

Building a skyscraper with a stone frame rather than steel or concrete not only reduces the encapsulated carbon content of the building, it costs less.

That was one of the themes of a much acclaimed exhibition at the Building Centre in London. But just as the exhibition began its two-and-a-half-month run, the Building Centre was closed down by the Covid-19 lockdown. It was the first time it had closed since The Blitz in World War II.

The exhibition has lately opened again in the Building Centre (read about that here). During its closure, the aims of the exhibition were transferred to the digital realm and can still be seen there. It includes a report called The Stone Tower Research Project, so architects, planners and clients can assess the case for sustainable stone structural frames.

The Building Centre’s exhibition, called The New Stone Age, was a celebration of the potential and beauty of structural stone, as well as its inherent sustainability.

It was curated by Amin Taha of Groupwork, Steve Webb of Webb Yates and Pierre Bidaud from The Stonemasonry Company, who came together as architect, engineer and craftsman to build 15 Clerkenwell Close in London, with its structural exoskeleton made from raw quarried Chomerac limestone from a quarry near Lyon in France. Some of the stone has a sawn finish, some still carries the marks of the drills and the split face where it was separated from the quarry face.

The raw nature of the stone gives the building a challenging aesthetic – and it was indeed challenged by Islington Council, which issued an order for it to be demolished, although after winning a RIBA award it was spared at appeal.

15 Clerkenwell Close is a seven-storey building in Islington that contains eight apartments (including Amin Taha’s own home) and several office spaces. Amin said he chose French rather than English limestone for the project to honour the original structure on the site, which was the 11th century Norman nunnery of St Mary’s.

He also said it was easier to obtain test results regarding the strength and nature of the French stone than it had been for English stones.

Price was not mentioned, but French limestones often are less expensive than British limestones because of the different geologies of the areas from which they are extracted.