Stone roofing slate: The significance of regional stone roofing on the built heritage

Twenty years ago this year a campaign by English Heritage called The Roofs of England came to an end. It had some success. Since then, Terry Hughes has continued to champion stone roofing.

Terry Hughes knows more than most and possibly more than anyone else alive about the stone roofing traditions of the British Isles. He is enthusiastic about passing that knowledge on and preserving the regional differences that help to define, architecturally, various regions of the country.

One of the ways he is sharing his knowledge is through his writing, extensive photographic library and videos on the website of the Stone Roofing Association (www.stoneroof.org.uk).

He has also worked with the National Federation of Roofing Contractors (NFRC) to help establish its heritage roofer scheme. It has three categories: Heritage Roof Master, Heritage Craft Roofer and Craft Roofer Operative.

A Heritage Roof Master has to have a Level 3 conservation qualification and is considered capable of taking responsibility for the design of a roof as well as the execution of its construction. They are able to work with architects, historians and other professionals to achieve a satisfactory specification for heritage roofing works.

A Heritage Craft Roofer can take responsibility for workmanship on a contract and supervise the work. A Heritage Craft Roof Operative is a craftsperson experienced in specific heritage roof types.

Once accredited, they are entered on the National Heritage Roofing Contractors Register (which you can see on the NFRC website at bit.ly/RoofMaster).

As ever, the success of the scheme depends on those in charge of the country’s built heritage making use of a scheme that can help them ensure they use qualified people, although Terry is critical of the sub-contractor culture in this country that is price-based rather than skill-based, to the detriment of heritage buildings. He is meeting with some of the professional organisations involved in the heritage sector later in the year to discuss this.

On the Stone Roofing Association website Terry says: “The British Isles have a great variety of roof types. They are especially rich in slating materials ranging from metamorphic schists and slates to sandstones and limestones. There is also a wide range of slating styles, demonstrating how slaters coped with often intractable materials and severe weather to produce weather-tight and durable roofs.

“These materials and techniques make a huge contribution to the historic landscape. They are as prominent in the cities, towns, villages and countryside as any other built element but are frequently misunderstood and poorly conserved, so that vernacular details and techniques are discarded and replaced with alien materials and inappropriate modern details. This need not happen. With care and forethought they can be saved.”

He quotes Sir Bertram Clough Williams-Ellis, CBE, MC, a British architect best known as the creator of the Italianate village of Portmeirion in North Wales, who died in 1978. “Traditional regional flavouring is well worth preserving for the sake of a world gone sadly flat. It should be a matter of pride as well as good sense, good economics and good manners for works to express themselves in accents that are recognisably regional and not harshly alien to an ancient tradition.”

Determining exactly what roofs would have originally looked like and how the materials on them were used does require some detective work. By the time renovation work begins, buildings might be on the ‘At Risk’ register with dilapidated roofs.

With laths or battens deformed and slates out of position, it is not always easy to determine the original roofers intention. So that is the first objective in order to decide precisely what the laps and gauges were.

Terry tries to do this to the nearest 1/4in (or 5mm) – a lot of roofing, especially on heritage buildings, is still measured in feet, inches and roofing squares.

Materials used might give some indication of a date for the roof – for example, the types of nails used – but the best evidence of how a roof and a building in general has evolved is more likely to be seen in the structure of the roof.

For those wishing to find out more about stone slate roofing, see the publications page on the Stone Roofing Association website at bit.ly/Stoneroofs3. Also see:

- Practical Building Conservation, 2013 Historic England – bit.ly/stoneroofs1

- The Pattern of Traditional Roofing, 2017, Emerton – bit.ly/stoneroofs2

Llandraw

The Roofs of England campaign that ended 20 years ago this year led to the opening of a new ‘delve’, as the extraction site is called, by Black Mountain Quarries to produce Llandraw sandstone.

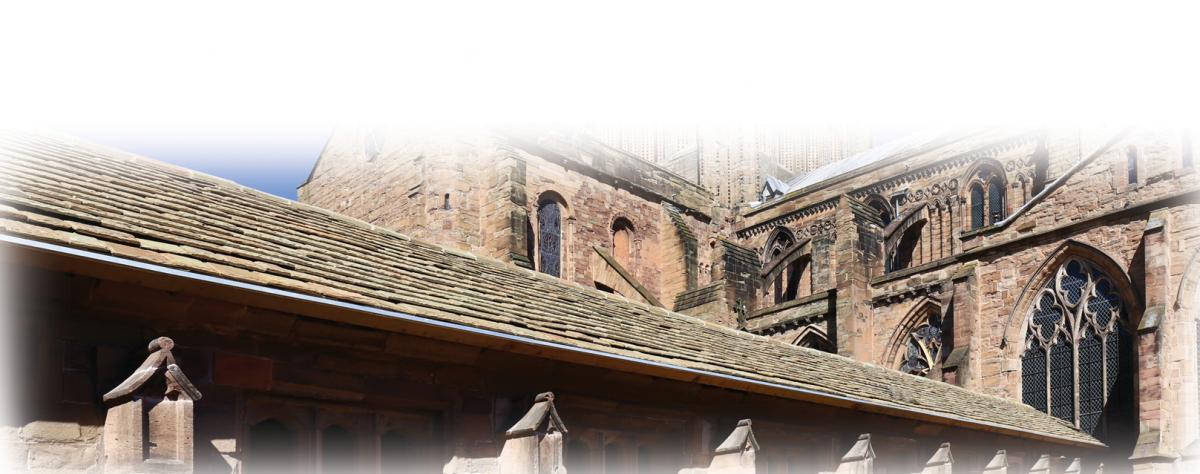

Llandraw stone roofing is now available and has been used on the roofs of a number of major buildings in the area, including the St John's Walk cloister at Hereford Cathedral, seen in the picture that goes across the bottom of these pages. It is a covered walkway linking the cathedral with the buildings of the College of Vicars Choral.

Llandraw sandstone, being produced within 20 miles of the Cathedral, was the perfect match. The hundreds of metres of roofing required were produced over a period of six months and stored until required by the restoration team.

Collyweston

One of the best known stone roofing slates is Collyweston limestone, which can be seen on the roofs of buildings in Stamford, Lincolnshire (pictured on the left).

Reclaimed Collyweston is in strong demand but there is not enough of it to go round, so last year Nigel Smith, director of Claude N Smith roofers, re-opened a mine on his land in Northamptonshire to start extracting Collyweston stone.

The stones clive naturally into thin sections for roofing when the ‘logs’ are left out in the frost. But as winters can no longer be relied upon to produce sufficient frosts, a refrigerated lorry trailer is being used for the purpose. That it could be was discovered by an English Heritage (now Historic England) investigation into how Collyweston could be artificially frosted.

Collyweston slate is available from Claude N Smith and the contractor Messenger in Stamford.

Slate roofing

Although all roofing stones are called slates, some of them actually are slate, and those from the UK come from Wales, Cumbria or Cornwall, with Wales the biggest producer.

Welsh slate was used for the new roofs of what was the first purpose-built gym in England when it opened in the 1860s.

The renovated Grade ll listed German Gymnasium is now a restaurant and a landmark in London’s King’s Cross regeneration.

It was re-roofed in 6,400 500mm x 300mm Penrhyn Heather Blue County-grade slates from Welsh Slate on the 600m2 of new roofs that were part of a 17-month renovation of the building by architect Allies & Morrison, which acknowledges the contribution of technical advice it received from Welsh Slate.

The original slates had been replaced using a bituminous felt covering. The new roof was laid by Attleys Roofing incorporating materials not in the original that were required to bring it up to modern standards – insulation, vapour control layer, counter battens, felt and battens, as well as the slate.

That increased the thickness of the roof, leaving the tiles above the gable parapets. To resolve this, the slates are separated from the brickwork with hidden gutters, valleys and leadwork detailing, which also reconciles the conflict between the precision of the new roof and the unevenness of the Victorian brickwork.

Considerations for identifying and using regional styles

Here is an example of two of the projects Terry Hughes has been involved with. They are recorded on the Stone Roofing Association website (www.stoneroof.org.uk) and are among many examples of projects detailing the considerations necessary when recreating regional roofing styles.

The slating contractor on both projects was Jordan Heritage Roofing.

Penmaen Cottage near Dolgellau was a conservation project and training programme supported by the Dolgellau Townscape Heritage Initiative, Snowdonia National Park Authority, the Heritage Lottery Fund, Cadw and the National Park’s Sustainable Heritage Fund.

The record created by Terry is in three parts (all videoed for Snowdonia National Park Authority):

- Investigation – looking at the roof details as the roof was dismantled

- Thinking about the details, whether they had been successful and if there was any reason to change them

- The re-slating project.

Recording the slating involved measurement of the slate lengths, their margins and the gauging for each course.

Higher Uppacott is a medieval farmhouse (longhouse) that originally accommodated people and cattle under a single roof. It is now a Grade 1 listed building of national importance because its development from its medieval beginnings is still clearly evident in the fabric of the building, and because it is one of the few remaining examples of this building type that retains its lower (or shippon) cattle shelter in an unaltered state.

Higher Uppacott is a medieval farmhouse (longhouse) that originally accommodated people and cattle under a single roof. It is now a Grade 1 listed building of national importance because its development from its medieval beginnings is still clearly evident in the fabric of the building, and because it is one of the few remaining examples of this building type that retains its lower (or shippon) cattle shelter in an unaltered state.

This lean-to as found had a roof of corrugated asbestos sheets. Evidence of an original slate roof came from a few old photographs. They showed the main slates were small and random sized. The eaves and verge slates were larger in the style typical of the South Hams district of Devon.

Although South Hams slating is well understood, there were a couple of features that had to be overcome at Higher Uppacott. Firstly, the top of the lean-to roof was tight underneath the deeply overhanging thatch, so it was impossible to get in to fix the slating laths in the normal way. This was resolved by making cranked lath cleats that could be driven into the side of the rafters from below.

Secondly, the small scantle slates were not made in a completely traditional format, so to make the new slating as authentic as possible Trevillet quarry allowed Terry Hughes and the roofers to select suitable slates and to measure and weigh a sample set of each length sufficient to cover 6m of roof.

From this it was calculated how many tonnes of each length would be needed to cover the whole roof.

St John's Walk cloister at Hereford Cathedral with its Llandraw stone slates.