Thibaut introduces waterjet for stone

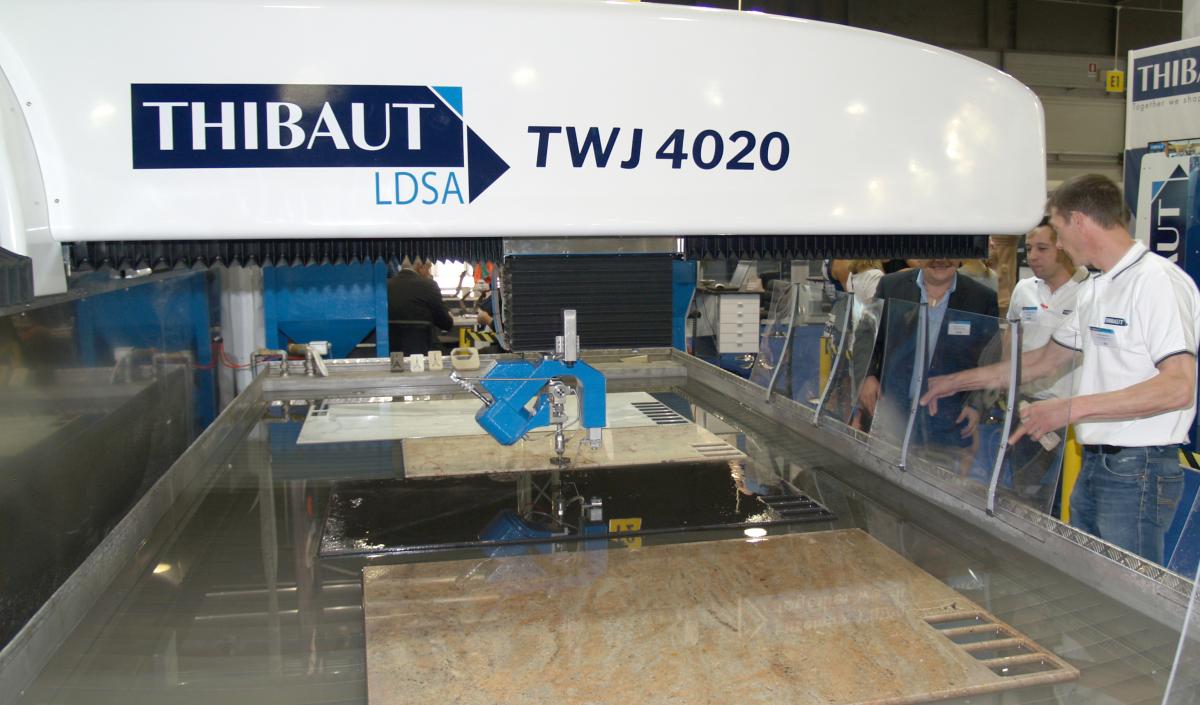

French stone machinery company Thibaut has teamed up with a French waterjet maker, LDSA, to offer a waterjet cutter for the stone industry.

Waterjets have become especially popular since the introduction of superdense sintered engineered stones, which have proved difficult to cut with discs, requiring their own tools. Some worktop companies now using engineered quartz, natural granite and the new sintered stones (such as LapiTec, Dekton and Neolith, to name three) have decided it is easier to use a waterjet that can switch from one material to another without tool changes to simplify the cutting.

Waterjets are unlikely to take over from bridge saws entirely because they are slower and use garnet for the cut, which adds to the cost. But they are being seen as a solution to a problem – although sintered stones are not guaranteed not to crack even with a waterjet and even when the outside edge has been removed before work begins in order to release the pent-up tension in the product.

Nevertheless, waterjets are in growing demand and Thibaut did not want to miss out. However, as it did not have waterjet technology expertise in-house, it has joined forces with a company that has been making waterjets for 25 years and created a Thibaut version especially for the stone industry. Actually there are two versions, identified as the TWJ 4020 and the TWJ 3317. One delivers 4,100bar pressure and the other 6,000bar. At 6,000bar the machine cuts faster but costs more to operate and maintain.

In either case, it has a diamond nozzle delivering the waterjet to minimise wear so that the machine does not have to be recalibrated so often and a bed of 4m x 2m to take the largest slabs. The watertank is separate from the machine with balast that raises the water level when the machine is cutting above the material being cut, which makes it very quiet. The arm can be moved out of the way to make loading and unloading easier and a sensor automatically measures the thickness of the material to be worked.

"We wanted a machine that gives you no worries," says Stephane Couteaud, who sells Thibaut machines to the UK. And Thibaut is confident enough it has achieved that to supply the waterjets with a full two-year warranty. "It is probably one of the highest quality waterjets there is because we decided not to compete on price, but to deliver the best quality for the best value."

For more information contact Stephane on SCOUTEAUD@thibaut.fr / mobile: 0033 6271 98184. Or see the website at the address below.

For more information contact Stephane on SCOUTEAUD@thibaut.fr / mobile: 0033 6271 98184. Or see the website at the address below.