Tiling : Avoiding mistakes

Sometimes the properties that give stone its uniquely attractive character need to be accommodated when choosing adhesives and grouts when laying stone tiles. Cyril Potter, Chief Chemist at Ardex, has some advice.

You need to take particular care in the selection of the most appropriate adhesive to use with stone tiles. This is recognised in BS 5385–5: 2009, which states that where adhesives are used with natural stone floor tiles or slabs “only those designed specifically for use with stone floor tiles and slabs should be used”.

It goes on to say: “Adhesives used should be capable of accommodating the bed thickness required to achieve solid bedding.”

Most adhesives are described as ‘thin bed’ adhesives and are unsuitable for use with uncalibrated stone tiles where the bed thickness can vary so much that a 10-20mm bed thickness is required to accommodate the variation.

There are adhesives that have been specifically designed for use at such bed thicknesses, such as Ardex S20 or X32, for example, which also have the advantage of being suitable for moisture sensitive stone tiles.

Stone tiles are not exempt from the trend towards large format tiles – in fact, the ease with which they could be produced in stone led the trend. But when fixing large format stone tiles on a floor it is essential that solid bed fixing is achieved.

This usually necessitates buttering the back of the tile with a thin layer of adhesive to ensure that solid bedding is achieved.

However, adhesives are available which have a rheology (or flow) such that solid bedding of large format tiles can be achieved without buttering the back of the tile. These are often described as ‘pourable’ adhesives – eg Ardex X7001, which is a rapid drying and hardening ‘pourable’ adhesive that can be trafficked and grouted just two hours after fixing.

Some large format stone tiles, particularly those which are thin and / or have defects that could weaken the stone, are sometimes reinforced on the rear face with a mesh such as glass fibre adhered in resin.

Where the resin is present over the whole rear face and is not compatible with cement-based adhesives (which it usually will not be), then it is usually necessary either to prime the back of the tile or fix in a reactive resin adhesive such as Ardex WA epoxy adhesive.

The problems commonly experienced with natural stone tiling are discolouration and staining. These typically occur during the bedding and grouting of the stone tiles.

Most of these problems arise as a result of moisture in the adhesive getting into the stone tile to the extent that there are visible effects on the surface of the tile.

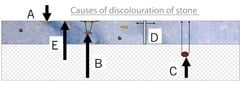

There are several causes of staining and discolouration of natural stone tiles and these are outlined in the schematic cross section through a natural stone tile bed in Figure 1.

The arrows show the directional movement of the contamination that causes the staining.

These causes are sometimes straightforward, such as surface contamination and spillage of materials on the surface of the stone tiling.

But other causes, such as minerals present in the stone being carried to the surface by moisture migrating through the stone, are less obvious.

The alkalis in the bedding beneath the stone tiling can also cause lime deposits to occur within and on the surface of the stone tiling.

The lime deposits can also fill capillaries within the stone so that light is not reflected back in the same way as it is from air filled pores. This is what makes the stone appear darker.

Some of the above effects are more likely to occur where there is sufficient water trapped under the stone tiles when they are bedded, or the bedding takes a long time to dry.

The inclusion of organic and metallic contaminants is more likely where cement and sand bedding techniques are used, since organic contaminants such as lignite or fragments of metal oxides and sulphides could be present in the sand.

Note that the thicker the bedding the greater the volume of water is present under the tiles.

Some forms of discolouration are irreversible and are often not uniform, which can mean that the appearance of the installed tiles differs noticeably from an unfixed tile and can therefore be unacceptable.

If soluble minerals are present, moisture movement toward the face of the tile can result in localised concentrations of such minerals. These can cause sub-surface discolouration of the stone tiling.

In these cases, the use of rapid drying adhesives and rapid drying grouts will help to avoid the discolouration problem.

The discolouration of natural stones tiles due to water absorption from the bedding can be a problem if the tiles are not solidly bedded, since differential discolouration can occur.

It is often the result of using the technique of blob fixing, which should be avoided in any case as it is a poor fixing technique that will concentrate loads and stresses to small areas of the tile and allow water penetration behind the tiling. With stone it can also lead to the blobs being visible through the tile.

Solid bed fixing is the recommended procedure. The correct technique is described in BS 5385-5: 2009.

The use of a rapid drying adhesive means that the free water from behind the tile, derived from the adhesive bed, is removed as part of the adhesive hardening process so that water staining is unlikely to occur.

But please note: Rapid drying adhesives should not be confused with adhesives that are solely rapid setting or rapid hardening. The use of Ardex S16 rapid hardening and drying adhesive virtually eliminates the risk of water staining due to its RapidDry formula. It also allows tiles to be trafficked and grouted 2-3 hours after fixing.

Where light coloured, translucent stone tiles are being fixed it is advantageous to use a white cement-based adhesive, since a dark adhesive would ‘grin’ through.

Also, if water staining is a possibility, the use of a rapid drying white adhesive would be preferable.

A problem that is occasionally seen is one where some thin ‘marble’ tiles swell up from the effects of moisture.

This can be a particular problem with certain large format, resin-based agglomerated stone tiles, which are particularly prone to warping as the backs of the tiles or slabs are wetted by moisture from the adhesive bed.

These tiles require the use of rapid drying adhesives or resin-based adhesives to ensure that warping does not occur. BS 5385-5 advises: “To avoid moisture from the adhesive bed distorting resin-based agglomerate stone products, reaction resin adhesives or quick drying low alkalinity cement based adhesives should be used.”

In some extreme cases – especially with certain ‘green marble’ agglomerated stone tiles – the warping occurs extremely quickly due to the presence of argillaceous clays that rapidly absorb water and expand. Warping can occur within minutes of bedding in a traditional cement-based adhesive.

Ardex have developed a system of products for use with natural stone that incorporate the unique ‘Rapidry Formula’ developed to provide practical solutions to these problems.

The mix water is literally ‘locked’ within the mortar, virtually eliminating the risk of water staining and ensuring risk free installation and a perfect finish every time.

Natural stone tiles that are particularly porous might also suffer from water staining on the tile face adjacent to the edges of the tiles. This is caused by the water from the grout penetrating into the edge of the stone tile and then to the face of the tile.

This effect is known as ‘picture framing’ and can be minimised by the use of products such as Ardex MG Rapid Dry Marble and Natural Stone Grout, a rapid drying grout.

Natural Stone Grout has been specifically developed for grouting natural stones, and can be walked on just 90 minutes after application. It is available in five colours designed to complement the colours of natural stone tiles.

Although certain types and sources of natural stone do have particular properties that need to be catered for in terms of particular adhesive and grout selection, it is important to bear in mind that the vast majority of quality natural stones do not give rise to problems.

However, due to the naturally occurring variations of a natural material it is not always possible to predict, simply by looking at a stone, precisely how it will perform. It is not always obvious that a stone will stain or bend.

To avoid the risks of such problems arising, it is not unreasonable to assume the worst and use rapid drying adhesives and grouts that will satisfy most situations.

Fig 1. The main causes of discolouration of stone tiles

A

Dirt entrained from above as a result of incorrect protection or cleaning

B

Rising moisture releases minerals contained in the natural stone

C

Discolouration from organic and other mineral contaminants in the bedding

D

Discolouration of the edges of the tiles from moisture in the grout mortar or from plasticisers on the movement joint sealant

E

Calcium hydroxide from the mortar bed migrates through porous stone to be deposited on the tile surface, where it becomes white calcium carbonate