We are all looking for ways to work smarter, not harder – and in recent years, technology solutions for the stone industry have become more efficient and more intuitive. Things we never believed machines could do have now become a reality. Of course, purchasing a large piece of equipment is a real investment and you’ll want to consider your options carefully.

To help you, we’ve put together this guide. You’ll be able to see most of this equipment on display at Marmo+mac trade show in Italy at the end of September but even if you can’t attend, here are some of the highlights.

Stone Automation

The Berkshire-based business which represent Donatoni Machine, Woodiam Diamond Tools and Slabsmith in the UK and Ireland will be flying out to Italy for Marmo+mac and will be available on the Donatoni stand to meet potential and existing customers.

Stone Automation have been the distributor of Donatoni for two years and offer a range of machines that can be used in conjunction with Woodiam blades. Recently, Donatoni launched the WaterJet – the J5.42 that has been designed and developed to meet the needs of stone fabricators looking for a reliable and easy-to-operate waterjet cutting system for processing different materials.

The centrepiece of the J5.42 is the cutting head, a compact and powerful 5-axis unit equipped with state-of-the-art technology. As well as this machine, Donatoni will also showcase the C4.38; Jet 625, P425, Z2000, Belt S3Q and Arm 3.

Two new products will also be revealed at the Donatoni stand – the MS Series, a new automatic slab-store and one other machine that is being kept under wraps for launch at the show

To find out more about these products, visit: stoneautomation.co.uk

Turrini Claudio system available from Stone Industry Group

Stone Industry Group

Led by Simon Bradbury and Gerry J Van Der Bas, Stone Industry Group are based both in the UK and in the US and provide and install water-treatment systems and dust-management solutions across the stone industry. Passionate about protecting the health of workers, Simon regular speaks about the risks of silicosis and encourages the implication of preventative measures including the use of dust monitors. The company, which represents Turrini Claudio (in the UK and the US), have also developed a fully-automatic water-treatment system called Clearly.

The company pride themselves on quick and friendly customer service and will offer a warm welcome to anyone who visits them on the Turrini stand at Marmo+mac.

Head to sig.ltd for more information.

Vetro

Vetro tooling is known for state-of-the-art tooling solutions and has distinguished itself by offering tooling solutions that deliver the exacting precision necessary for such tasks. Included in this is expertise and passion in redressing diamond tooling – a solution designed to extend the life of these essential tools, ensuring consistent performance while delivering significant cost savings.

Diamond tools are engineered to handle the most demanding tasks such as stone cutting, drilling etc, however the intense friction and heat generated during use gradually wear down the diamond edges, reducing their effectiveness. Without proper maintenance, tools can lose their cutting efficiency, leading to increased downtime, high operating costs and potentially compromised project quality.

Redressed diamond tooling by Vetro (before and after)

Redressing is a process that restores the original shape, sharpness and balance of a worn diamond tool. By removing the worn layers and exposing fresh diamond, the tool is effectively rejuvenated allowing it to perform at peak efficiency once again. This process not only extends the life of the tool but also ensures that it continues to deliver the precision cuts and finishes that are crucial in high-stakes applications.

Diamond tools represent a significant investment and frequent replacement can quickly add up, especially in this industry where the tools are used extensively. Redressing provides a more economical alternative by restoring tools to like-new condition at a fraction of the cost of purchasing new ones. This service allows companies to maximise the return on their investment.

In addition to the financial benefits, redressing also contributes to sustainability efforts. The manufacturing of new diamond tools is resource-intensive, involving the extraction of raw materials and significant energy use. By extending the life of existing tools Vetro Tooling’s redressing service reduces the demand for new tools. This aligns with the growing emphasis on sustainability across industries, helping companies meet their environmental goals while maintaining high levels of productivity.

David Lithauer, Vetro’s managing director, said: “We understand the importance of minimising downtime in any production environment. Our redressing service is designed with convenience in mind offering quick turnaround times to ensure that customers can get their tools back into operation as soon as possible. Our streamlined in-house process – from tool assessment to redressing and return – ensures that disruptions to the production schedule are kept to a minimum with return time usually within five days. Our many years’ experience in the glass and stone industries gives us a deep understanding of the unique demands of diamond tooling, we are well-equipped to provide advice and support on tool maintenance and care.”

Find out more at: vetrotooling.com

FOCUS ON…Stonegate

Dan Clark of Stonegate offers an insight into Dal Prete’s line up

Stonegate have been supplying Dal Prete water-treatment systems throughout the UK and Ireland for over three years now, and they are becoming a familiar sight for stone fabricators serious about working with good quality water. These water-treatment systems are proven to save on water consumption and extend tool life, but that’s not all.

The systems are highly automated. However, far from being more complicated, the system is intuitive and easy to understand. All elements are designed to be very low maintenance, even down to the use of ultrasonic sensors instead of probes to reduce manual cleaning. While you will be provided with full training from the Stonegate technicians, the systems are designed to be easily accessible for all users and chances are you will pick it up in no time.

Dal Prete water-treatment system

The systems come with the option of an integrated filter press, which compresses the waste into small bricks. This massively reduces the need for manual labour, saving potentially hours each week. Because the plant is automated, the filter press can be programmed to press, so there’s no risk of forgetting and silt going off and hardening! Also, not only is the solid waste extremely easy to get rid of (positively impacting disposal costs), but it also means the area around your water filtration system isn’t dirty or wet. The filter press process also eliminates the familiar sight of bags of sludge sat outside of the factory drying out before it can be disposed. Or in many cases – not drying out!

Coagulant and flocculant dosings are customised to the specific needs of your factory and are automatically dosed, so it’s super simple – plus there’s no risk of forgetting to dose or making an error with the dosage amount! This is not only better for your machine, as the dosage is always perfectly consistent, but it’s better for your pocket too, as you can be sure you’re only adding what you need.

Stonegate have a team of trained Dal Prete specialists, who have spent extended time in Italy with the manufacturers undertaking dedicated training. Their experience of multiple installations in the UK and Ireland and also the ongoing support they provide as part of their position of tooling and support providers, means they are fully embedded in your water filtration journey. They are ready to offer advice on the full water treatment cycle from your clean and waste water tanks to your pipes and drainage channels to find the best solution for your factory, and as part of this mission to improve water quality in stone workshops, they are now offering Clean Water Assessments, to allow you to fully understand your processes and how they might be improved. See: stonegatetooling.com

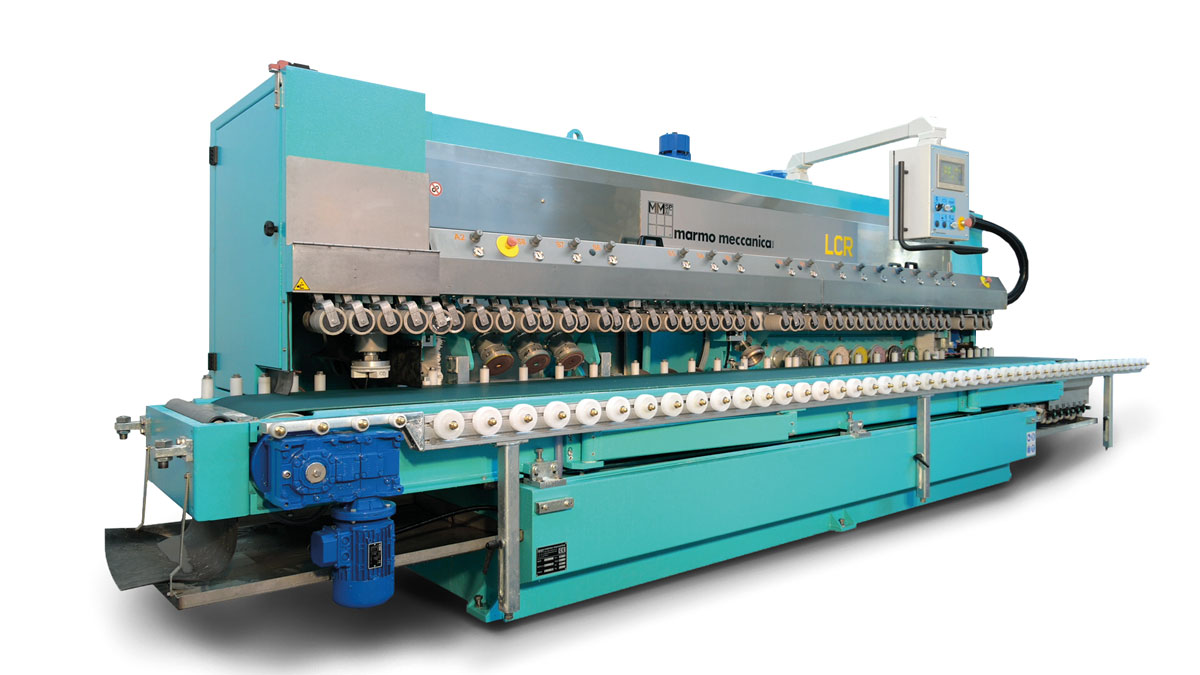

Marmo Meccanica's top-spec LCR edge polisher available from Stone Equipment International

A new chapter for Marmo Meccanica and Stone Equipment International in the UK

In May 2024, the acquisition of Stone Equipment International, also known as National Masonry Ltd, was announced by Stonegate Precision Tooling Ltd. The business, which has been well established in this country for well over a decade was most commonly known as the UK and Irish agent for the Marmo Meccanica edge polisher machines. Stonegate are well embedded in the stone industry, as suppliers of tooling and consumables, but also as CNC tooling experts and providers of water-filtration and laser-templating systems.

Stone Equipment International, formerly headed by Andy Bell, held the exclusive distribution rights for Marmo Meccanica edge polishers since 2010, where they took over the agency from stone and equipment wholesalers Pisani. During that time, it became a common occurrence to see the range of turquoise-coloured vertical and horizontal edge polishers in workshops and factories. The model followed by Andy Bell, enabled fabricators to part exchange their old machines for new Marmo Meccanica systems, saving time, costs and freeing up space quickly. The new owners plan to follow this successful model but also to add the benefits of having extensive UK and Irish sales and technical teams, enabling them to be able to assist and support customers in their edge polishing requirements.

Marmo Meccanica edge polisher machines have traditionally been seen as ‘entry level’ edge polishing machines. This is a common misconception born from the fact that many smaller factories starting out see the LCV vertical edge polisher as a good machine to begin with, as it’s compact, perfect for workshops without a large footprint, and very easy to use and maintain. The reality, however, is that Marmo Meccanica offer a wide range of edge polishing machines. From the aforementioned LCV to the LCH, horizontal polishers and the top-spec LCR specialist pencil round and straight edge polisher. All Marmo Meccanica machines are built on modular systems, meaning you can add and remove heads, wheels and blades to best suit your working processes, water consumption and factory layout.

The wide range of machines means that the new Stone Equipment International team are able to assess their customers’ needs and recommend an edge polisher that works specifically for their individual requirements. The sales team and technicians have visited the factory in Italy and undergone extensive training, meaning they can assist in pre-assessment and installation, but most importantly they will be there down the line to provide after-sales support. In the stone industry there are always improvements that can be made, with the right support and guidance, to improve end result and efficiency. Stone Equipment International, just like Stonegate, will aim to provide this exact assistance for their customers. Head to: stoneequipmentinternational.com

FOCUS ON…Prodim

Netherlands-based company is best known for its Proliner digital templating solution

Accurate countertop measurement is crucial for a seamless installation and more professionals are now turning to digital tools like the Proliner. This machine simplifies measuring straight, curved, and complex shapes with remarkable speed and precision. Its accuracy and portability are driving more companies to adopt digital measurement technology.

Ferrara Quarzi, a Sicilian company, has used the Proliner Stone package to create digital and precise measurements of kitchen countertops, among other projects. Currently, Ferrara Quarzi own five Proliners, assigned to different technicians in various regions: Sicily, Campania, and Lazio, but are extending services to other regions and even extending its expertise abroad.

Sara Scalisi from Ferrara Quarzi said: “On a typical day, each technician conducts four to five measurements, demonstrating the Proliner’s effectiveness. It seamlessly integrates with mobile devices, allowing instant connection to our office from anywhere in the world.”

Countertop designs have embraced bold patterns and designs to add character to kitchen and bathroom spaces. From intricate quartz veining, inspired by marble, to terrazzo-like surfaces, homeowners are drawn towards countertops that are not only functional but also artistic expressions and focal points of home design.

For a more straightforward and intuitive design experience, Prodim has also developed PC software that seamlessly integrates with the benefits offered by the Proliner – the Prodim Factory Software. Not only does it allow easy designing of various production pieces with correct measurements and perfect fits, but it also visualises what the final project will look like, considering the choice of one material over another. Specifically, of one slab over another.

The Factory Fabricator configuration (especially the Slab Creator module) contains photogrammetric technology capable of doing exactly this, at the click of a button, without struggling with complicated science or investing in expensive equipment.

In the era of customisation, homeowners seek countertops that reflect their personal style and preferences. Tools like the Proliner measurement device enable precise customisation, even for complex projects. The Prodim Factory software further enhances customisation by allowing the creation of libraries of customised materials and digital inventories.

Efficiency and safety are crucial in countertop installation. Innovations like prefabricated countertops minimise adjustments on-site, while new assembly systems improve stability and durability. Integration of digital platforms facilitates seamless coordination between designers, manufacturers, and installers, ensuring a high-end result.

This year, sustainability continues to drive home design, leading to the significant adoption of eco-friendly materials like recycled glass and porcelain for kitchen countertops. Proliner technology is becoming increasingly popular due to waste reduction and efficiency, reduced on-site visits, and decreased carbon emissions during construction.

To learn more about the Proliner, visit: prodim-systems.com

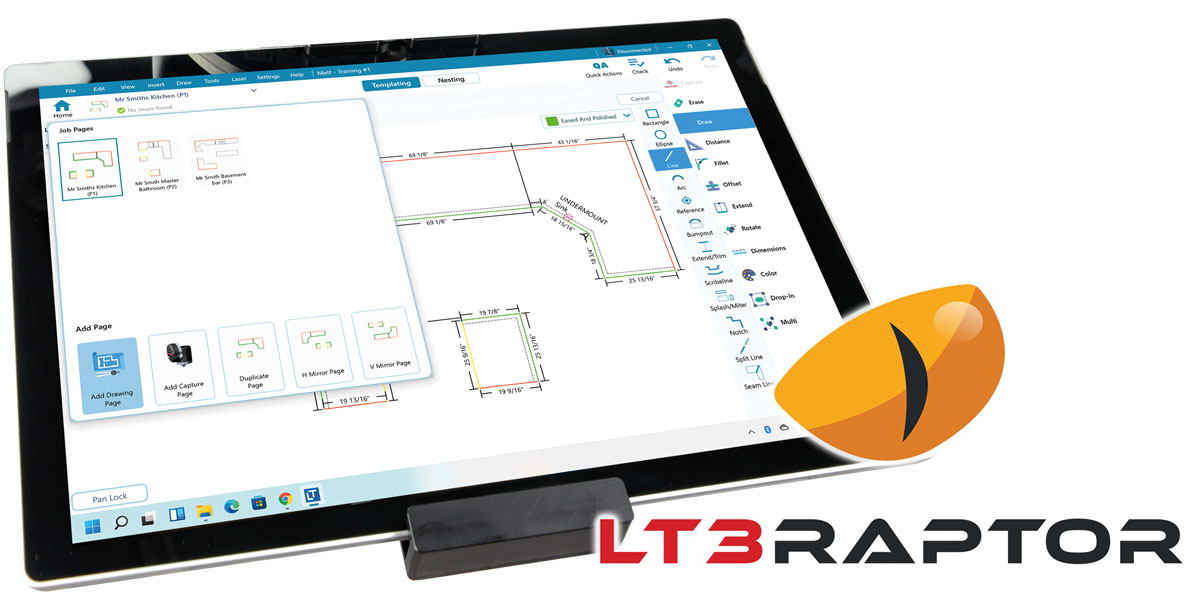

LT3Raptor digital templating tool from LPE Group

LPE Group

The LPE Group offer the LT3Raptor digital templating platform designed with a robust cloud-based management hub to help companies be faster and more efficient not only in templating, but all areas of their process, including job management, programming, quality control, and more.

Manage and track all jobs, assets, activity and more throughout your entire process from this cloud-based management hub. Set up customer jobs ahead of time for your templators, including job/order details and customer agreements, to speed you up in the field and enhance scheduling. Easily confirm job details and capture sign-offs from customers at the jobsite.

LT3Raptor is a quick way to create fabrication-ready files, optimising your company's efficiency and productivity. Obtaining written and visual documentation and customer approvals on site is critical to your business and customers. LT3Raptor allows you to collect and organise all your information in one comprehensive package.

Some of the new features in LT3Raptor, including scribelines, scribetabs, and offsets and intelligent nesting for efficient slab layout and fabrication, allow you to speed up your file prep and programming processes to help optimise your workflow and increase production.

Become more organised and efficient in your fabrication process with the StoneTag label system by LPI. Designed to optimize workflow, StoneTag allows you to track and label every component of your job, ensuring a seamless journey from fabrication to installation.

This new Software as a Service (SaaS) platform encompasses a myriad of functions and tools that subscribers will have access to including LT3Raptor, LPI Cloud, StoneTag label system, and LPI Learning Management System (LMS). This evolution is designed to revolutionise customers’ experience with the brand's products and services, bringing a wave of continuous innovation, efficiency, and seamless collaboration. For more information, visit lt3raptor.com / lpegroup.ltd

CMS Kosmos bridge saw

Stone and Glass Group

With a wide range of equipment, the Stone and Glass Group offer Sasso’s edge polishers and surface polishers and, at this year’s Marmo+mac will be exhibiting Flying Bull and Flying Flat.

Flying Ball

Sasso created Flying Ball as the perfect machine to polish flat and round edges, offering several options to complete the work. It offers hot-dip galvanisation and can be configured with multi-purpose spindles for special workings, in addition to normal edge polishing. It’s also possible to work on very large and very thick pieces.

Flying Flat

For polishing kitchen tops or wall claddings, there is Flying Flat – a manually programmable edge polisher, equipped with patented devices to provide you with superior productivity. This compact bit of kit is a complete vertical flat edge polisher in only 2.4 metres. It's perfect to work pieces from five to 120cm.

K600

The K600 interpolated 5-axis CNC bridge saw that embodies the evolution, history and success of Sassomeccanica in the world further improves its performance. Compact, powerful, precise and reliable machine, ideal for linear, curved and angled cuts and for the realisation of complex shapes, it is considered among the most precise on the market. The monobloc structure with high rigidity, completely hot galvanised, has been redesigned to incorporate the electrical panel and make it even safer.

The Stone and Glass Group also offer CMS Brembana machinery which includes:

Speed CNC

A machine with three/four interpolated axis monobloc machining centre. Brembana speed is a Numerically Controlled Machining Centre with three/four interpolated axis suitable for processing both slabs and blocks even with high thickness in marble, granite, composite stone, and ceramic.

It can perform each type of raw and polished contouring, as well as milling, drilling, countersinking, bas relief, and writing. This machine can also be customised.

Kosmos Bridge saw

This 5-axis CNC monolithic bridge saw is a new generation of a numerically controlled 5-axis bridge saw. It’s extremely compact and easy to install; it doesn’t require any foundations, even as a possible re-installation. This machine is built with the needs of workshops in mind and it is used for cutting slabs up to 200mm thickness of natural stone, synthetic stone, and ceramic.

The weight of the machine, up to 5.1 tonnes, ensures the perfect rigidity for the production of: kitchen countertops; vanity tops; wall panels for interiors and exteriors; flooring; doorsteps; staircases; thresholds and street furniture.

Easyline water jet

The Brembana Easyline is a high-performance, versatile, modular water jet cutting system – either pure or hydroabrasive – which can be employed in a number of application fields for the most diverse production demands:

The cantilever structure, with a separate tank, allows an easy access to the worktable. Loading and removing material is quick and easy.

All axis’ motions are carried out through hardened and ground rack and pinion.

The thermowelded bellows provide complete protection of the guides and the rack from water and dust.

The steel structure undergoes an anti-rust treatment through sandblasting and ceramic painting, which results in a higher resistance against corrosion.

The tank is set up for the installation of a dredge system for the abrasive removal.

Brembana Easyline is also available with the following configurations:

Twin (solution for pendular working with double tank)

Twin+ (single-tank pendular cutting system)

Dual bridge

Scanner safety

Manual pivotable 3-axis head

Kartesia automatic CNC

This 3- or 4-axis numerically-controlled machining centre with automatic stop and suction cup positioning system is a three/four-axis interpolated machining centre operated by Numerical Control for processing marble slabs, granite, synthetic stone and ceramics. This machine is the ideal solution for quickly and accurately performing any kind of edge contouring, rough or polished, milling, drilling, countersinking, bas-reliefs and lettering.

Worktable tooling is handled fully automatically by the machine and does not require any human intervention; this solution significantly increases productivity while ensuring a small footprint. Learn more at: stoneandglassgroup.co.uk

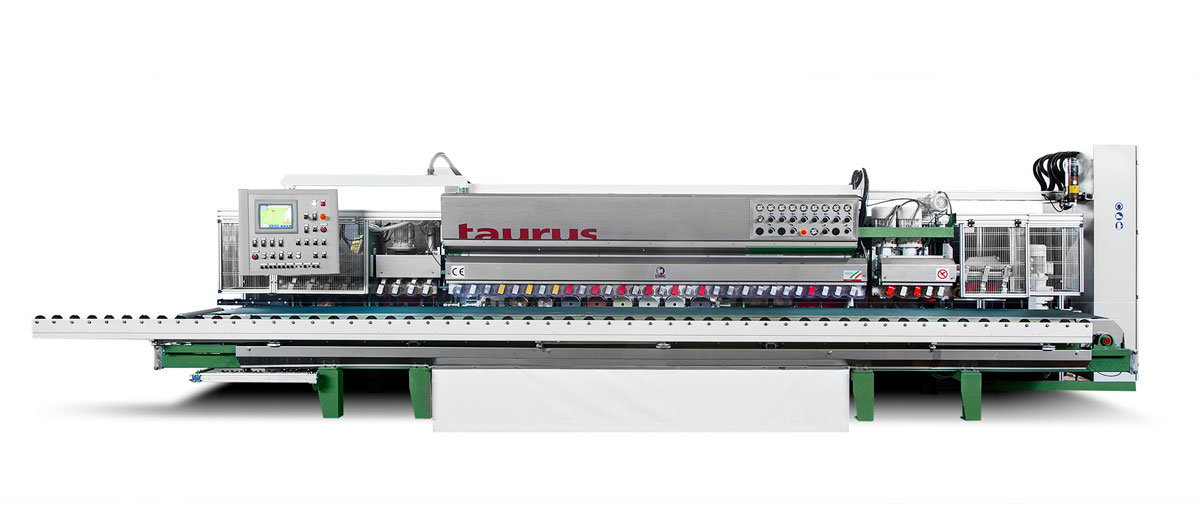

CMG Taurus edge polisher

FOCUS ON…Zambelis

Jasper Zambelis offers his roundup of products available through Zambelis

OMAG Area5 Advanced

A versatile and robust cutting CNC working centre, using the latest technology and expertise of over 50 years.

The Area5 Advanced is designed to do cutting, shaping, profile and polishing in a single machine, which is fully customisable to the fabricator’s needs.

The machine can take up to a 850mm diameter blade automatically and has a tool station to hold various CNC tooling, including stubbing wheels, profile wheels and carving tools.

With the addition of probes, camera, and vacuum suction pads, it has accuracy and productivity at the forefront, by measuring and automatically adjusting blade and tool wearing, as well as material vein matching and an innovative vacuum system to manipulate pieces.

The machine has a tilting table with a dual surface of aluminium and wooden panels, which can be used for bridge saw and CNC working when vacuum cups are necessary to hold the stone in place. There is a range of gearboxes for metal wheels, polishing pads and blades, which can be used for making grooves, cutting and edge polishing.

Additionally, the tool station can be configured to accommodate spring system plates to hold abrasives for face polishing with Frankfurts.

The machine is suitable for many sectors of the stone industry, ranging from kitchen fabrication, stone masonry, 3D architectural work, fireplaces, cladding and memorials. As all the blades and tools are able to be picked up by the machine automatically, pieces of work that require many hours and different tools can be programmed to work independently during the night, without the need of an operator present.

Achilli

The popular GOLD, a high-precision 4-axis bridge saw will be on display, which is a perfect starting point for fabricators looking for a saw that has amazing features and is suitable to cut a variety of materials, including Dekton.

It has a tilting table, automatic head rotation through a full 360º, motorised head tilt, and a variable speed 11kW motor.

Achilli also plans to show its TFM mini bridge saw, which can be customised as required with options such as a 7.5kW or 11kW motor with an inverter, a galvanised frame, manual or motorised pop-up rollers, side extensions, water tank and recycling system and laser alignment.

CMG

The popular Taurus is a versatile machine for flat and bullnose materials, including porcelain. It is customisable to include pre-cutting units, calibration units and specified profile wheels.

Giacomini

Giacomini are able to provide expertise in bridge, derrick and gantry cranes – you can meet the team at Marmo+mac.

Italmecc

Since 1985, Italmecc has specified in water clarification and dust purification worldwide, and offer a wide range of solutions. The range includes wet and dry dust booths (Airbox & AirDry) and complete water clarification systems, with flocculent chemical dosing stations, booster pumps with inverters, silos and submersible pumps.

Dal Forno

Dal Forno will have a wide range of vacuum lifters on display at Marmo+mac as well as a jib crane, which are customisable to individual needs and lifting requirements. These include single pad lifters for small blocks to 3- and 5-pad lifters for slabs for use in kitchen fabrication.

Terzago

Terzago will present a variety of their innovative and well-known 4 and 5-axis bridge saws, with the latest EasyStone NC software, which can be customised based on the customer’s needs and the work that needs to be carried out with a blade range of 625mm to 1m. Also, the traditional range of block cutting and other primary saws. For more info, see: dzambelis.co.uk