This is background to the new BS8415 for specifying memorials written especially for Natural Stone Specialist readers by the The National Association of Memorial Masons (NAMM).

British Standard BS8415:2005+A2:2012

(Monuments within burial grounds and memorial sites – Specification )

The latest version of the British Standard for memorials was published at the end of April this year. The standard BS8415 was first introduced in 2005. In 2008 it was reviewed and the main text was re-published in 2009. In 2010 a further review and re-evaluation began and it has taken two years to reach agreement on the revisions.

As part of the review, British Standards Institute invited input, suggestions and comment from the memorial masonry industry, including those involved in the manufacture and selling of memorial ground support systems.

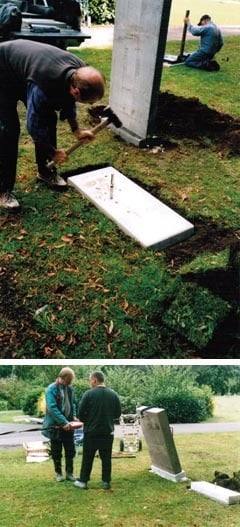

Memorial ground support systems can be anything from a simple poured concrete foundation, to the more commonly used stainless steel pin system, or ground anchor, as it is widely known, or the shoe system preferred by the MOD and Commonwealth War Graves Commission.

In the days before the standard was introduced, the memorial masonry industry was generally unregulated. Many memorials were fixed on inadequate or unsuitable foundations. Evidence of this can be seen where memorials have fallen or been pushed over with just three or four bricks supporting quite substantial headstones.

Sadly, the emphasis put on the foundation of the memorial and employed by the Victorians seems to have been ignored as memorials became smaller, especially after World War Two. It is evident that in many cases the foundation was not seen as having much importance and those who installed memorials on inadequate foundations were creating major problems for those who would inherit the responsibility for burial grounds and memorials years later.

In the late '80s and early '90s the National Association of Memorial Masons (NAMM) was beginning to realise the risks posed by such poor foundations and practices. NAMM attempted to introduce some regulation into the industry and the existing NAMM Code of Working Practice was further developed with more emphasis being put on the correct type and size of foundation to use in regard to the size and weight of a memorial.

NAMM began to look at different ways in which the memorial masonry industry could be self regulated and in 1995 appointed Professor John Knapton, Professor of Structural Engineering at Newcastle University, to carry out tests and studies into the stability of and memorial construction, including foundations and memorial support systems.

Professor Knapton’s findings were also used to stipulate the type and specification of materials which should be used to hold a memorial together as well as the type and specification of foundations or ground support systems. The idea was that a standard could be set that would apply across the whole of the UK.

In July 2000 a child died as a result of an incident in a Harrogate Cemetery and the Health & Safety concerns regarding memorials became a major issue for Burial Authorities. Hundreds of memorials were laid down or pushed over in the name of Health & Safety. This in turn caused a public outcry and it was clear that some form of regulation was required.

The industry itself was already well aware of this issue and began taking steps to ensure that safety became high priority, while trying to ensure that common sense should prevail regarding testing of existing memorials and the methods employed in making them safe.

In 2005 the first British standard for memorials was published. NAMM altered its Code of Working Practice to comply with the requirements of the new standard. In the British Standard a section on the procedure for the testing of existing memorials and how to deal with those found to be a risk was introduced, and one of the sections of the new standard (Annex F) dealt with the way memorials and their fixing components should be tested, including setting minimum specifications for materials. Professor Knapton’s calculations were used to enable this section to be completed.

The British Standards Institution allowed NAMM to monitor this testing, ensuring it was carried out to the requirements of the standard. NAMM was also allowed to maintain a register of those devices and systems which met the criteria.

Since then, NAMM has led the way with ground anchor testing and approval. Once a ground anchor or fixing system has been tested and approved by independent structural engineers, a certificate is issued to the manufacturer confirming approval and the anchor or fixing system is added to the list of approved fixings.

All anchors and systems tested before this year's amendments to BS8415 have met this criteria and the soil conditions used for the original tests have been confirmed by the structural engineers as meeting the requirements (described in Section 5,3,2,1a of the latest standard).

Representations regarding changes to the type of soil conditions, testing procedure and testing requirements for ground anchors and fixings were voiced during the two year consultation process but these were overruled and rejected. The procedures used by the structural engineers and used over the past 15 years were seen to be more than adequate and were written into the revision of Annex F.

It is worth noting that since the introduction of the British Standard in 2005, and since the promotion and use of approved fixing systems have become compulsory, no serious injuries or accidents have been reported.

In January 2009, The Ministry of Justice developed and issued their “Managing the Safety of Burial Ground Memorials“ guidance document that was underwritten by the Health & Safety Executive and includes reference to the British Standard: "More recent memorials should be designed to BS8415 and the construction, dowels and fixings should be in accordance with the National Association of Memorial Masons (NAMM) Code of Working Practice. Memorials installed to these practices have greater assurance of good stability." (www.justice.gov.uk/downloads/burials-and-coroners/safety-burial-grounds.pdf)

The introduction and development of the two national registration schemes for memorial masons (BRAMM and the NAMM Register) for those who install memorials, along with the revised British Standard, the Ministry of Justice guidelines and the NAMM Code of Working Practice, has resulted in the industry being able to claim that it is now self regulating. New innovations and fixing methods are still encouraged provided they meet the requirements of the standard BS8415.

The replacement of time-based guarantees for memorials – cemetery operators were increasingly demanding 30-year guarantees – with a certificate of compliance has placed the responsibility for fixing memorials to a proper standard firmly with the memorial mason. The emphasis has been on making sure the public and the burial authorities can have memorials erected in burial grounds with the confidence that they will be safe and secure many years after installation.