Dr Martin Kirk, Director of Kirk Natural Stone Developments in Turriff, Aberdeenshire, admits that ‘20mm Facing System’ is not the best brand name ever devised, but it goes some way to explaining what his latest development is.

Kirk Natural Stone Developments sell just about everything in stone from granite and quartz worktops to kit houses. Martin Kirk says he is passionate about building in stone.

But he doesn’t like waste and when he saw structurally sound but ugly concrete buildings around him being demolished he thought there had to be a better way of using them.

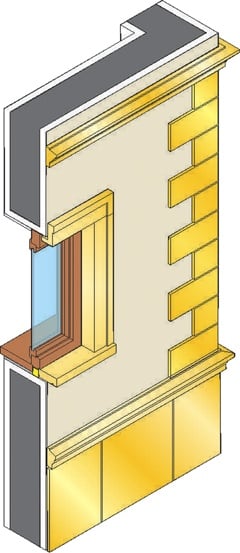

His solution was to devise a stick-on 20mm thick stone facade to convert the tired old concrete buildings into bright, attractive stone buildings.

The building has to be surveyed accurately, then the 20mm facings are manufactured off-site – a long way off-site in Poland and China – often using Chinese granite because of the price advantage and because a lot of buildings in Aberdeenshire are granite. The individual elements produced are stuck on to the building using Dunlop Setfast Plus.

Setfast Plus has a holding strength of 3kN, which ought to be strong enough to hold stone on its own and is all that is used by Kirk Natural Stone up to 3.7m. However, above 3.7m additional mechanical fixings are used. Martin believes they are entirely superfluous but he is following the British Standard for stone panels that says mechanical fixings should be used.

He says using stone cladding in this way costs about £230/m2 on the finished wall, which is a lot cheaper than demolishing a building and constructing something new. It even compares favourably with rainscreen cladding, which can be in the region of £400/m2.